New battery powered torque wrench ITH ADS with class-leading weight-to-power ratio

22.03.2016

The smallest and lightest battery-powered nut runner (battery powered torque wrench) with torque capabilities up to 4,000 Nm (2,950 ft*lbs) was developed by ITH Bolting Technology. Read our press release and download the PDF-file.

The new battery driven torque wrench model ADS has the best power-to-weight ratio (Nm/kg) of its class coupled with an industry-leading high battery capacity of 5.2 Ah. The ITH type ADS also features a brushless motor (wear-free) with automatic shut-off when the target torque value is reached. A high precision of ± 4% is possible due to the intelligent torque control system which automatically adjusts the rotations per minute (rpm) throughout the bolting process.

The high-capacity 5.2 Ah battery makes the ITH type ADS the ideal torque tool for all bolted connections bigger than M16 (3/8”).

High-capacity battery 5.2 Ah is essential to lasting performance

Battery-driven nut runners are ideal for use on sites where power supplies are not – or not easily – available. When considering battery performance people often overlook the importance of capacity in Amperehours and only focus on voltage (V).

Capacity is integral to untiring performance. “The higher the capacity, the more power can be stored”, Dipl.-Ing. Frank Hohmann explains, who leads the worldwide acting family-run company ITH Bolting Technology together with his brother Dipl.-Ing. Jörg Hohmann. Based on this, the decision was made to use a 5.2 Ah 18V battery when developing the new torque tool.

Consistent development: small, light, and powerful

Next to endurance the key factors for battery torque tools tools are size and weight to guarantee the best handling possible – especially on applications where space is limited.

“Getting the best out of these key factors was our target during the development process. We followed this approach consistently and are confident with the result”, Frank Hohmann says.

The first battery-version of the ITH Nut Runners series was successfully introduced five years ago. This new 3rd generation introduces a newly designed high-performance planetary gear drive which had a significant role in achieving the class-leading power-to-weight ratio (Nm/kg).

Features of the nut runner type ADS: ergonomic and user-friendly design

In addition to the automatic shut-down feature which occurs when the target torque value is reached, the ITH type ADS has another feature known as Automatic Free-Run which eliminates the torsional binding that can make it difficult to remove a torque tool after tightening each bolt. The ADS-3 automatically frees itself for the user making it safer, faster, and easier to move from bolt to bolt.

The positioning ring allows the gearbox unit to be rotated in 360° and independently of the drive and then locked into position which makes setup at each bolt quick and easy. During the bolting process the tool endures all of the reaction forces, protecting the user from any strain.

Smart nut runner electronics: precision and feedback for the user

A high precision of ± 4% is achieved by the redeveloped „ITH Soft-Turn-Automatic“ which continuously readjusts the rpm of the brushless electronic motor according to the bolting procedure. The user receives feedback about the bolting process from the motor LED, which is placed on the back of the housing:

- Procedure in-process (LED flashes slowly),

- Target torque reached (LED lights up permanently),

- Error or battery low (LED flashes quickly).

Using ADS Professional or Basic, two extra LED-lights on the foot of the non-slip pistol grip shed light on the bolted application for a clear working environment.

Universal use

Battery nut runner ITH type ADS can be used for service-jobs on all bolt connections bigger than M16 (3/8’’) like for example:

- Wind turbines (especially offshore)

- On construction sites: cranes, construction machines of all types, HV-standard bolt connections of common steel constructions (I-beams)

- Common machine engineering bolt connections

Battery nut runner applications in the picture slideshow

Download the press release

Contact your local person in charge

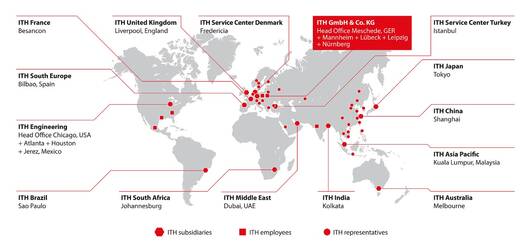

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

Related content

-

Battery-powered torque wrench ITH nut runner type ADS is the smallest and lightest battery torque tool up to 6,000 Nm (4,425 ft*lbs) - see the video.

-

Testing and controlling torque values during the tightening process with all types of ITH Nut Runners: Documentation of the applied torques with the battery-run Torquemeter.