Cranes

Bolting technology for cranes

Precision and safety for the highest demands

Crane systems place the highest demands on safety, reliability and efficiency. ITH Bolting Technology offers innovative bolting tools and customized solutions for construction cranes, tower cranes and offshore cranes. As an independent system supplier, we provide you with objective advice and work with you to develop the optimum bolting solution – for long-lasting connections and maximum operational safety.

Applications at a glance

Reliable bolt connections on all crane components

Whether slewing bearings, corner bar connections in steel construction or foundation bolt connections – the requirements for bolt connections in cranes are varied and demanding. ITH Bolting Technology supplies the right solution for every application and supports you from selection to commissioning with technical advice and on-site service. Discover an excerpt of our applications here.

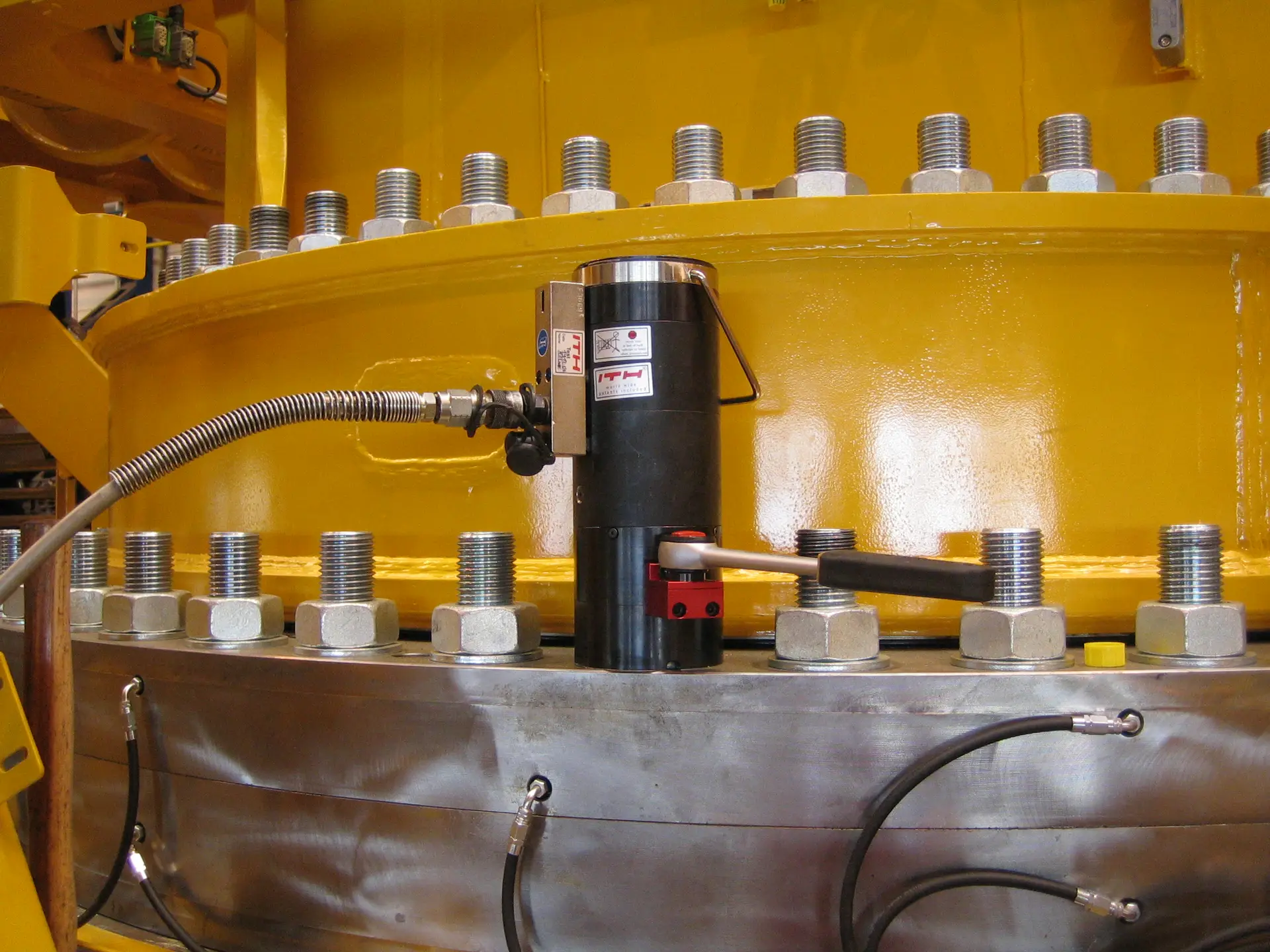

slewing bearing

The slewing bearing connects the slewing tower to the substructure and has to absorb enormous loads. ITH supplies high-precision bolting tools for this purpose, which ensure uniform and secure pretensioning.

Corner bar connection

The corner bar connection is a central element in the steel construction of cranes. With ITH solutions, these critical connections can be bolted efficiently and in a controlled manner – for maximum stability.

Trust worldwide

Your partner in bolting technology

ITH Bolting Technology has been a reliable partner in numerous industries for over 40 years. With innovative solutions, a global presence and first-class service, we set standards in quality and reliability.

Industries

Discover our sectors

Contact us

Request advice

Frequently asked questions

Which bolting tools are suitable for slewing bearings on cranes?

Hydraulic torque wrenches such as the DRS and electric high-torque wrenches such as the EDS are mainly used for slewing bearings on cranes. These tools enable precise, uniform and secure pre-tensioning of the bolt connections – even in confined space conditions and at high torques.

How does ITH ensure the quality and safety of the bolt connections?

ITH is setting standardized processes according to DIN ISO 9001, regular maintenance and calibration of tools as well as documentation of all bolting processes. Quality is ensured by trained specialist personnel, digital documentation systems and annual inspections – also directly on site at the customer’s premises if required.

Does ITH also offer individual advice and on-site service for crane projects?

Yes, ITH offers objective, technical advice on all bolting applications as well as a comprehensive on-site service. This includes inspections, maintenance and calibration of tools directly on the construction site or in operation. This provides customers with tailor-made solutions for their specific requirements.

What are the advantages of using ITH Bolting Technology for foundation bolt connections?

ITH bolting tools ensure maximum precision and traceability during the assembling and maintenance of foundation bolt connections. The tools are designed for large bolt diameters and high pre-load forces / preload and enable safe, efficient and documented assembling – even under difficult conditions.

Are the ITH bolting tools compatible with different crane models?

The ITH bolting tools have a modular design and can be adapted to different bolt sizes and crane models with different inserts and reaction arms. Customized versions are possible at any time, so that almost all common crane models can be covered.

How can I request a technical consultation or inspection?

You can request a consultation or inspection quickly and easily using the contact form on the ITH website or by telephone. A special service request form is available for maintenance and calibration, which you can conveniently fill out on your PC and send to ITH.

Is there an on-site service for inspections and technical advice?

ITH offers technical advice and optional inspections of bolt connections directly at the customer’s site.