Power plants

Bolting technology for power plants

Precision and safety for critical connections

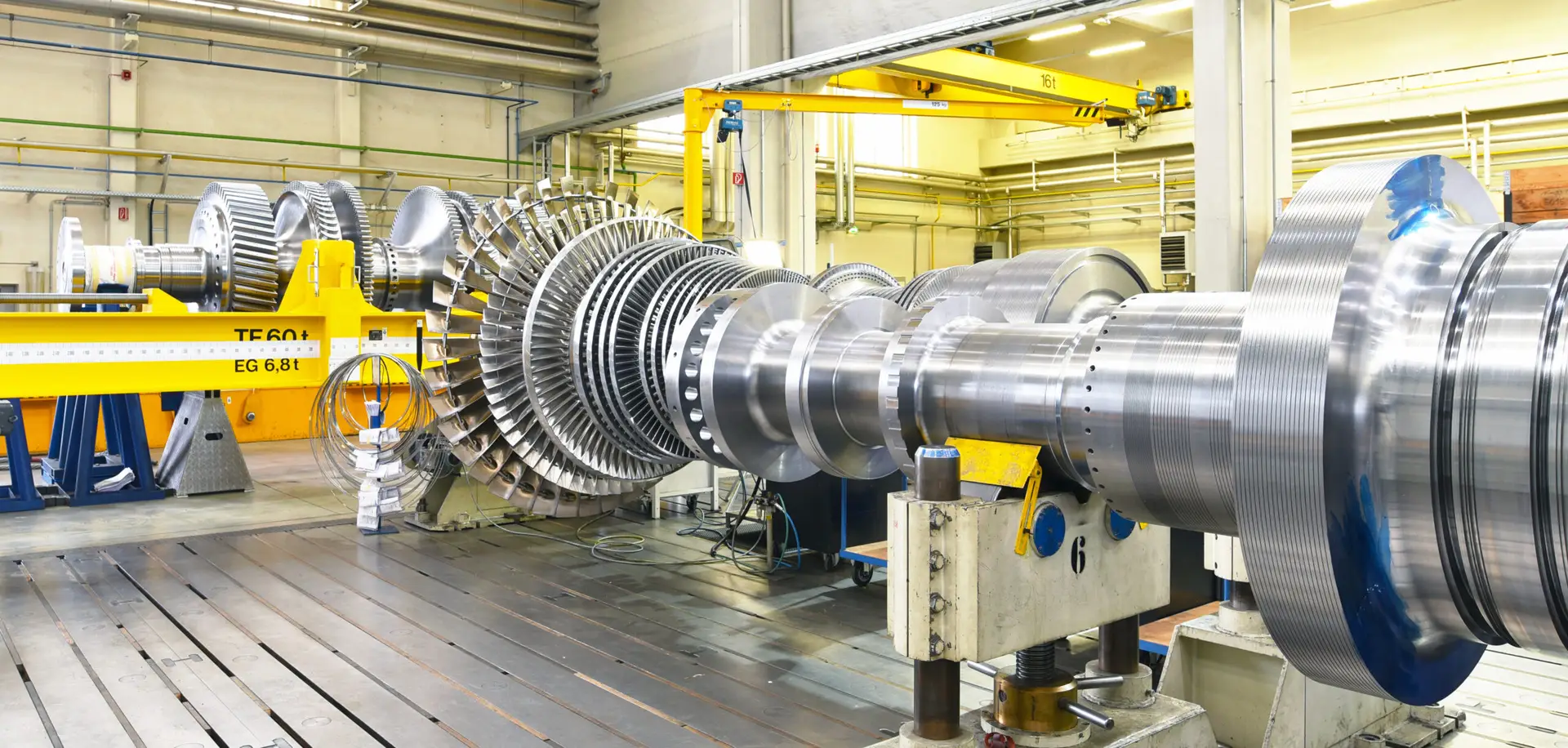

Power plants place the highest demands on the safety and reliability of every single bolted joint. Since 1980, ITH Bolting Technology has been your experienced partner for innovative bolting tools and solutions that are specially tailored to the complex challenges in power plants. From steam generators to high pressure pumps and valve fittings – we offer you customized systems for tightening and loosening bolts to ensure that your plants operate safely and efficiently.

Applications at a glance

Precision and efficiency for every bolt connection

In power plants, bolted connections on central components such as steam generators, pumps and valves are crucial for the smooth operation and safety of the entire plant. ITH not only supplies you with the right tools, but also provides you with objective and independent advice on selecting the optimum bolting process. Our solutions are tailored to the specific requirements of the power plant sector and help you to minimize downtimes and carry out maintenance work efficiently. Discover an excerpt of our applications here.

High pressure pumps

The bolt connections on high pressure pumps have to withstand extreme loads. With ITH bolting technology, these connections can be securely tightened and loosened to ensure trouble-free operation of the pump systems.

Trust worldwide

Your partner in bolting technology

ITH Bolting Technology has been a reliable partner in numerous industries for over 40 years. With innovative solutions, a global presence and first-class service, we set standards in quality and reliability.

Industries

Discover our sectors

Contact us

Request advice

Frequently asked questions

Which bolting tools are particularly suitable for use in power plants?

Hydraulic pre-load tools and powerful torque tools from ITH, which have been specially developed for large bolt diameters and high pre-load forces, are particularly suitable for power plants. They enable safe, precise and efficient tightening and loosening of bolted connections on critical components such as steam generators, pumps and valves.

How does ITH support me in selecting the right bolting process for my application?

ITH offers objective and competent technical advice – by telephone or directly on site. Our experts analyze your individual fastening case and recommend the technically and economically optimal fastening method, regardless of the system.

Can ITH tools also be used for maintenance work on existing systems?

Yes, ITH bolting tools are designed for assembling as well as for the maintenance and repair of existing systems. They can be used flexibly and are also available briefly | temporarily as rental tools to carry out maintenance work efficiently.

What advantages do hydraulic pretensioning tools offer compared to classic torque wrenches?

Hydraulic pre-tensioning tools enable friction- and torsion-free tightening of bolts, resulting in a very precise and uniform pre-load force / preload. This increases operational safety and minimizes the risk of leaks or damage to the connection.

How does the technical consultation and on-site inspection by ITH work?

Following your inquiry, our experts will work with you to analyze the requirements of your bolted joint. If necessary, we will carry out an on-site inspection to determine the best solution and provide you with comprehensive advice – independent and manufacturer-neutral.

Are individual special solutions for special bolt connections possible?

In addition to standard tools, ITH also develops and manufactures customized special solutions for specific requirements in power plants. Our engineers support you from the planning stage through to the implementation of your individual bolting solution.

What service and maintenance services does ITH offer for power plant customers?

ITH offers a comprehensive service package: from regular maintenance and calibration of tools to fast procuring spare parts and individual service concepts. All services are carried out worldwide and by qualified specialists – even directly on your premises,