Oil, Gas & Petrochemicals

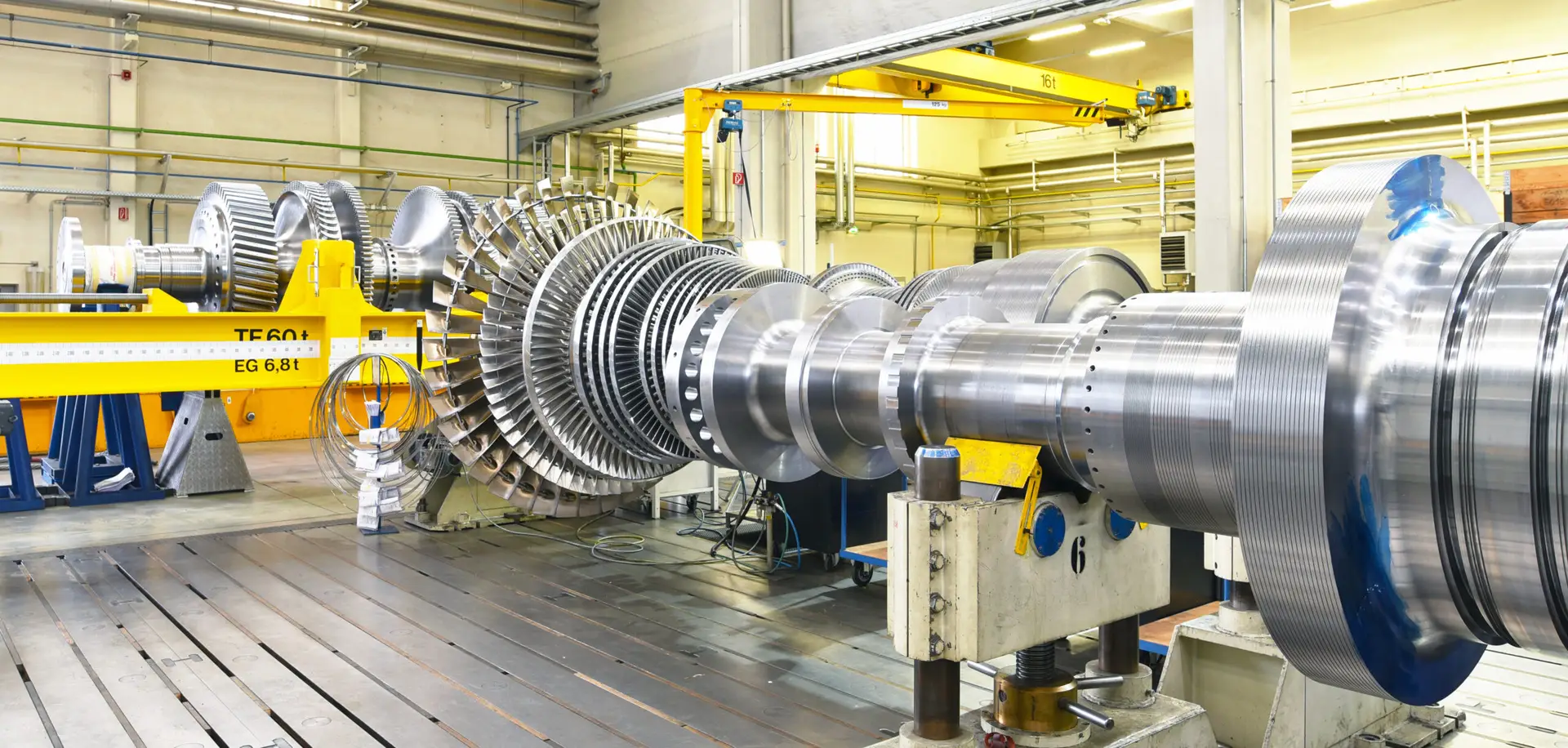

Bolting technology for oil, gas & petrochemicals

Safe & efficient

The oil, gas and petrochemical industries place the highest demands on the safety, precision and reliability of bolt connections – both onshore and offshore. ITH Bolting Technology offers customized solutions for the safe tightening and loosening of bolt connections in critical applications. Our hydraulic and pneumatic tools enable reproducible preloads, reduce the risk of leaks and ensure maximum operational safety – regardless of the power supply.

An excerpt of our applications

Precision and efficiency for every bolt connection

In the oil and gas industry, bolted connections on flanges, heat exchangers, pumps and compressors are crucial to the integrity of the entire system. ITH supplies innovative tools and systems to assemble and maintain these connections efficiently, safely and with the highest precision. Especially in high-pressure applications and explosion-risk areas, our solutions ensure reliable results and minimize downtime. Discover an excerpt of our applications here.

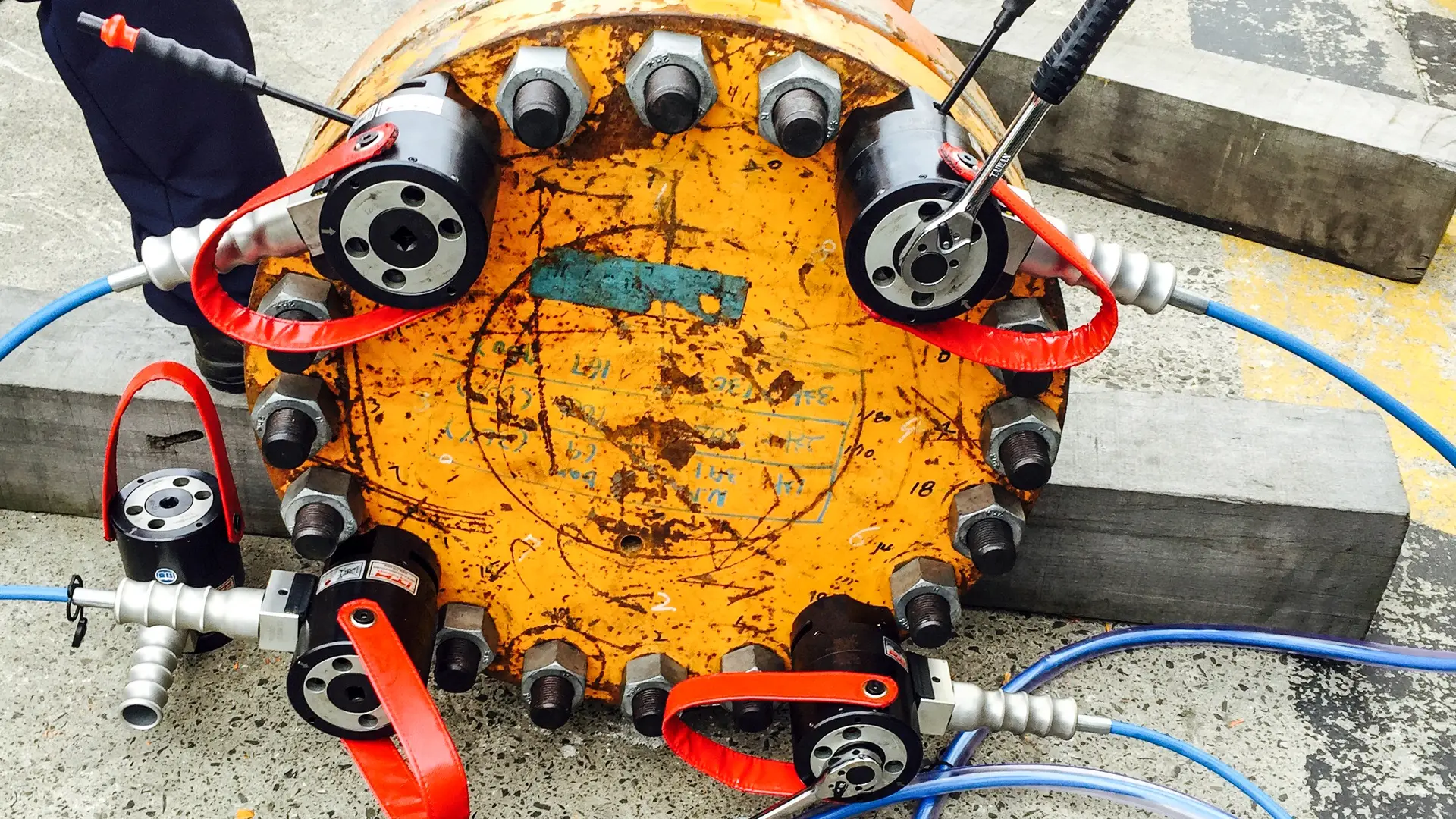

ANSI and ASME flange

Flange connections are central elements in piping systems. With ITH Multi-Tensioning, several bolts can be tensioned simultaneously and evenly, which significantly reduces the risk of leaks.

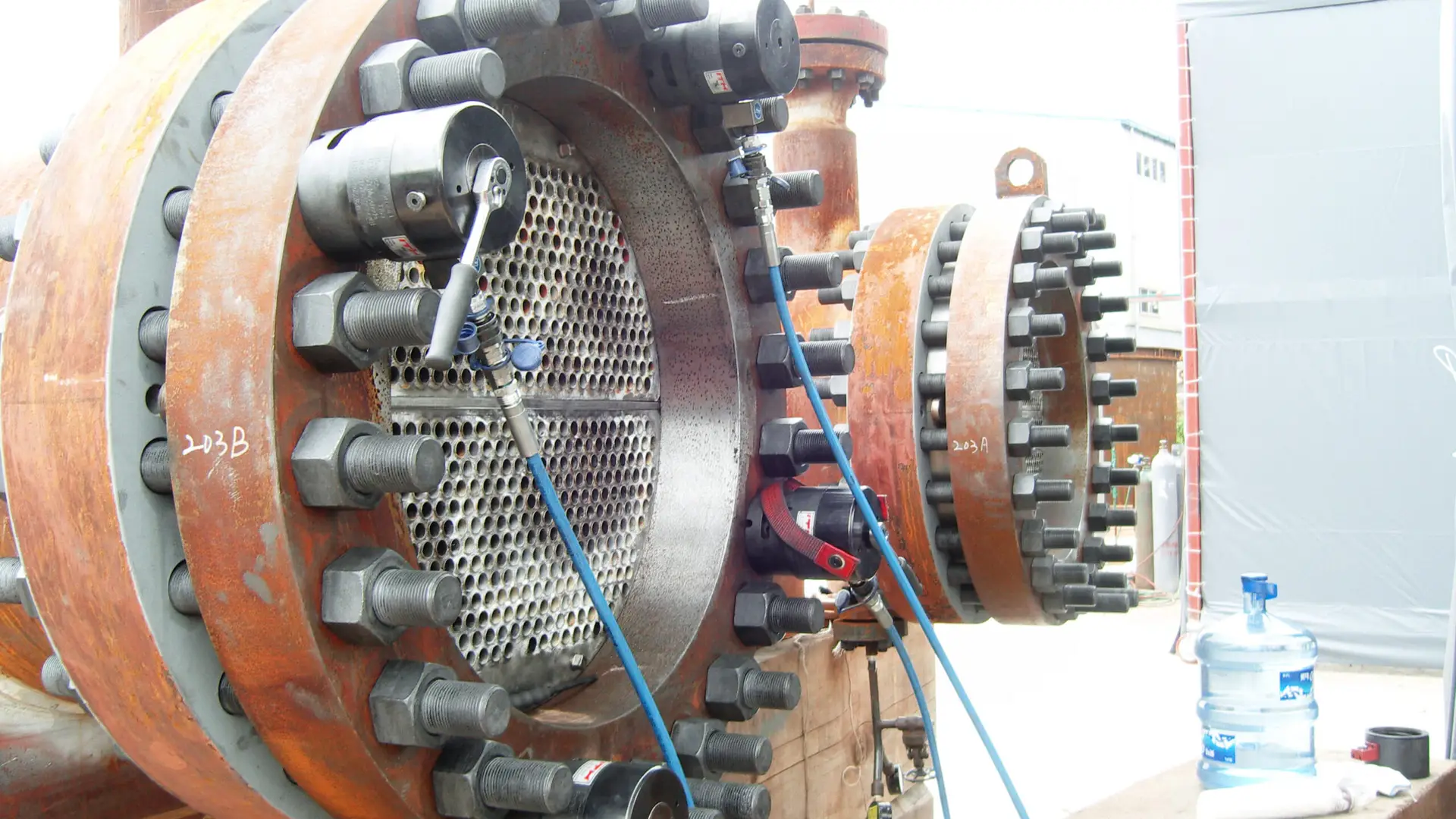

Heat exchanger

Bolting connections on heat exchangers have to withstand extreme pressure and temperature changes. ITH tools ensure a precise and permanent preload to maximize operational safety.

Trust worldwide

Your partner in bolting technology

ITH Bolting Technology has been a reliable partner in numerous industries for over 40 years. With innovative solutions, a global presence and first-class service, we set standards in quality and reliability.

Industries

Discover our sectors

Contact us

Request advice

Frequently asked questions

How can the risk of leaks at flange connections be minimized?

By pre-loading, pre-tensioning several bolts evenly with the ITH Multi-Tensioning System, a precise and reproducible preload is achieved, which significantly reduces the risk of leakage.

What are the advantages of the ITH stretch method for bolt connections?

The ITH stretch method enables a tight preload tolerance of ±2.0 % and ensures uniform loading of the bolt connections, which increases operational reliability.

For which petrochemical applications are ITH tools particularly suitable?

ITH solutions are suitable for flanges, heat exchangers and flange covers – wherever maximum precision and safety are required.

Does ITH also offer technical advice and on-site service?

Yes, ITH offers objective, technical advice and an optional inspection of the bolt connections directly at your site.

How can I select the right tool for my application?

Contact us for individual advice – we will recommend the best technical and economical solution for your bolting application.