Research and development

Research and developmentSetting new standards with more than 200 patents | Pioneer in quality management | Cooperations with leading technical institutions

Since 1995 all processes at ITH are certified according to the quality guideline DIN ISO 9001 : 2008

with leading technical institutions and universitys

Bolting tool innovation and process quality

Continuous Improvement

With more than 30 years in the bolting industry, ITH continuously invests experience and know-how into new technical developments. Many designs that ITH developed are now industry standards.

More than 200 national and international patents prove the innovative capabilities of ITH.

Many of these developments have become standards of bolting technology.

Pioneer in Quality Management

In 1995 ITH was the first company in the market that was certified by the strict quality regulation of DIN ISO 9001. This strong commitment to quality persists.

Technical and efficient economic benefit

We are continuously working to innovate and improve quality. Our customers benefit from technically optimized bolted joints and efficient, cost effective bolting tools.

Cooperation and development of standards

ITH has close partnerships with leading scientific institutions for the research and development of new bolting technology.

A lot of cooperative research and numerous succesful projects have already been completed. We are working together with the universities and insitutions RWTH Aachen, Ruhr University Bochum, Technical University Darmstadt, Technical University Dortmund, Fraunhofer Institute, ZeMA Saarbrücken, University of Applied Sciences Southwestfalia (at Meschede and Soest) and University of Applied Sciences in Zwickau.

Furthermore ITH contributes to the development of new technical standards within the German VDI (Association of German Engineers) and within the ISO (International Organization for Standardization).

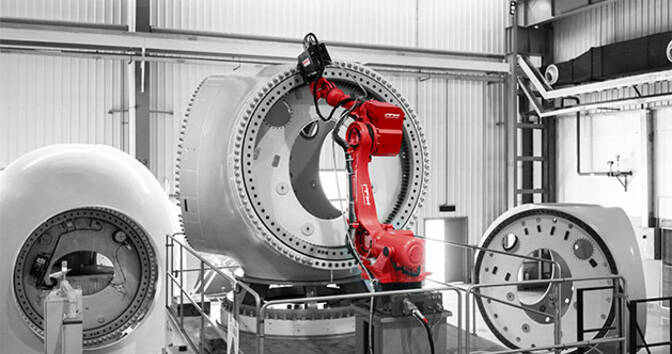

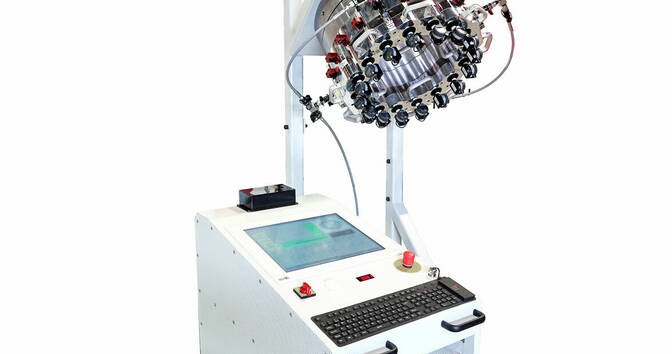

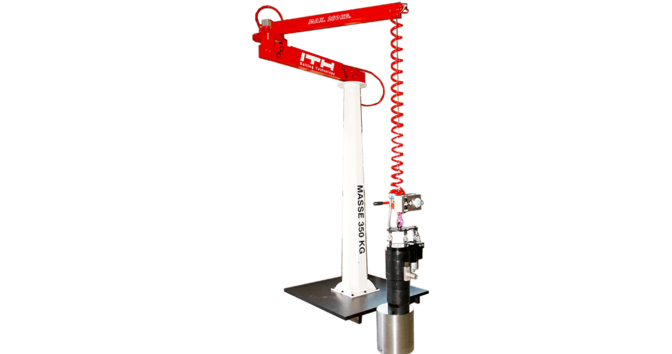

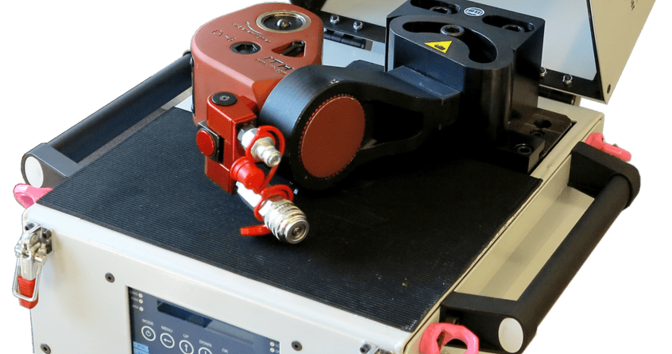

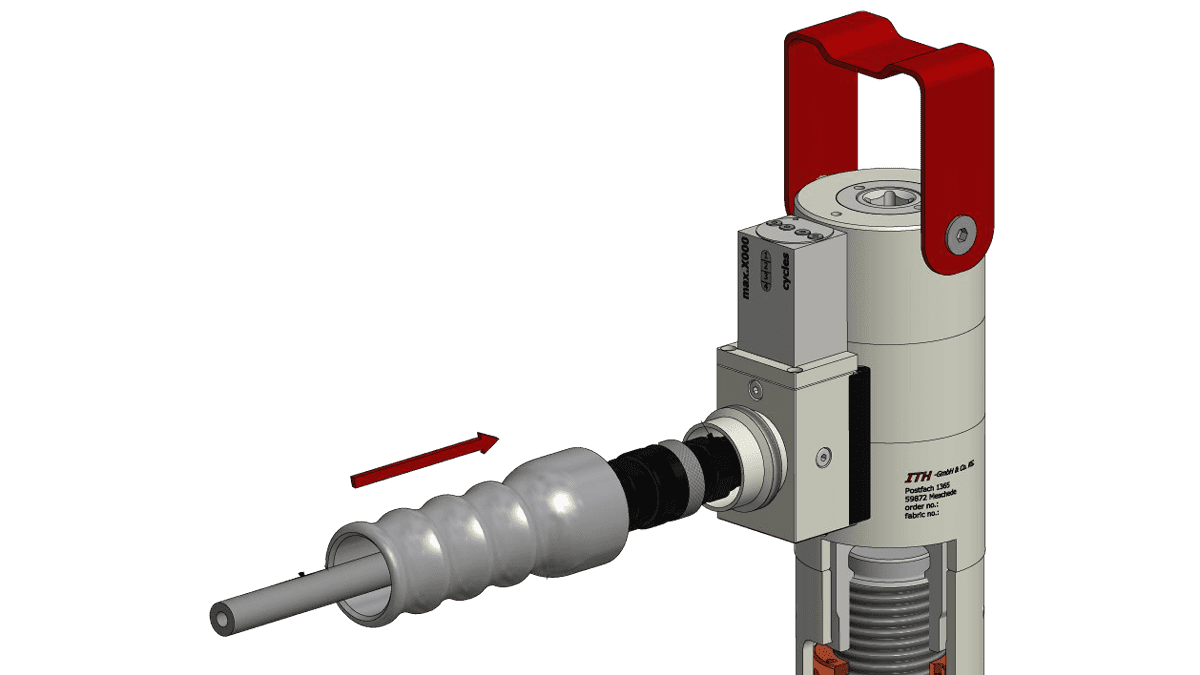

Innovation in bolting technology: examples

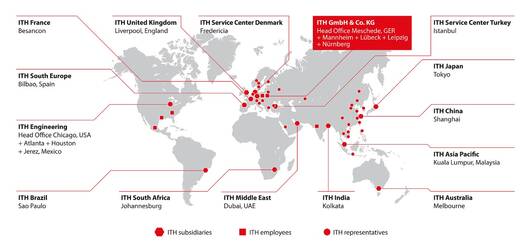

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

-

Overview high pressure hydraulic pumps for bolt tensioning cylinders and pumps for hydraulic torque wrenches: Electric, battery-driven, pneumatic or manual pumps.

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Overview of all types of hydraulic torque wrenches, working due to the torque method or torque-angle method.