Hydraulic bolt tensioning: friction-free and torsion-free

Worldwide leader of hydraulic, friction- and torsion-free tensioning

ITH Bolting Technology is the worldwide market leader for hydraulic, friction- and torsion-free bolt tensioning (ITH Stretch Method). In 1979 the founder of ITH - Hans Hohmann - first introduced the bolt tensioning process to the gas and steam turbine industry. This concept of engineering innovation has been a part of ITH since the beginning.

Throughout the years ITH has earned more than 200 international patents and numerous customer and industry specific solutions which have become a standard within the bolting industry. These accomplishments combined with a continued dedication to engineering innovation have proven ITH as the market leader for hydraulic, friction- and torsion-free bolt tensioning.

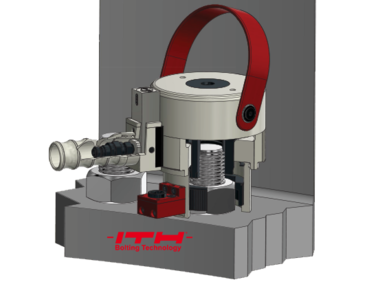

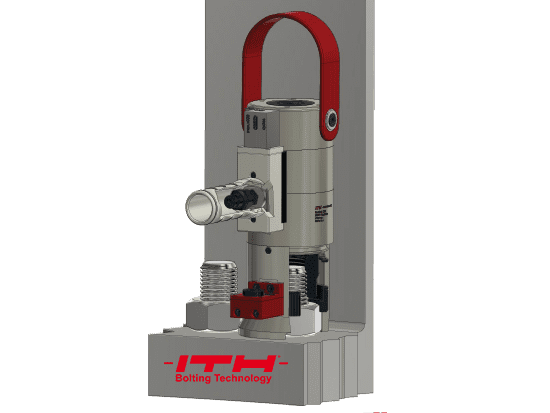

Hydraulic Bolt Tensioning Cylinders, single-stage designs

-

Bolt tensioning cylinders with one piston surface and without automatic piston return for low bolting cycles. For applications with axially limited and radially free space.

-

Bolt tensioning cylinders with one piston surface and automatic piston return for high bolting cycles. For applications with axially limited and radially free space.

-

Bolt tensioning cylinders with one piston surface and with automatic piston return for high bolting cycles. Designed with a hollow piston to be applied on long protruding threads like foundation bolts, heat exchangers or flanges.

-

Bolt tensioning cylinders with one piston surface and with automatic piston return for high bolting cycles. With innovative ITH quick exchange mechanism for different bolt designs. Designed to match common flange standards.

Hydraulic Bolt Tensioning Cylinders, multi-stage designs

-

Bolt tensioning cylinders with multiple piston surfaces and automatic piston return for high bolting cycles. For applications with axially free and radially limited space.

-

Bolt tensioning cylinders with multiple piston surfaces and automatic piston return for high bolting cycles. Designed with a hollow piston to be applied on long protruding threads like foundation bolts, heat exchangers or flanges.

Hydraulic Bolt Tensioning Cylinders: special designs

-

Two-tensioner merged design for simultaneous tensioning of tightly spaced bolts

-

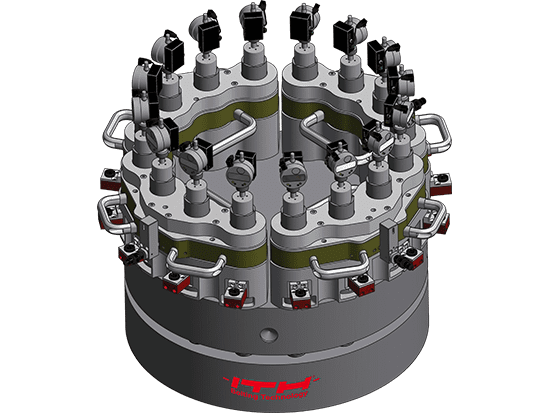

Tensioning flange bolts in one operation with multiple tensioners combined into single unit design.

-

Large cylinders to tighten and loosen big bolts M150 - M800 (6'' - 31 1/2'').

Advantages of the ITH Stretch-Method

- Free of friction and torsion: Hydraulic bolt tensioning with the ITH Stretch Method guarantees reproducible pre-tensioning forces within a close tolerance of ±2.0 %.

- Small αA-factors up to 1,05

According to German bolting guideline VDI 2230 "the tightening factor αA takes into account the scatter of the achievable assembly preload [forces] between FMmin and FMmax". FM = assembly preload. The smaller αA-factor, the more efficient you can design bolted connections. - Because it is a system free of friction, there is no need to consider the friction coefficient variable during the design process of bolted connections.

- The hydraulic pressure input of the bolt tensioning cylinder has a linear relationship to the pre-tensioning force output, which leads to a high degree of reproducibility.

- High pre-tensioning forces can be achieved with compact tool dimensions

- No torsion or bending forces within the bolts during the bolting process extends the life of the bolts.

ITH safety concept

- ITH patented safety features for bolt tensioning cylinders: cycle counter, safety handle, safety fracture device

Speed

- Fast working procedures by a weight-optimized tool design, automatic piston return, fast pressure build-up of the hydraulic pumps

- Parallel tensioning of more bolts at the same time (ITH Multi-tensioning system)

- No unwanted movements of the bolted parts because there is no reaction moment involved

Flexibility

- Interchangeable support piece of the Bolt Tensioning Cylinder for different nut and washer configurations

- Interchangeable change bushing of the Bolt Tensioning Cylinder for different thread sizes

Durability

- Less wear and tear on tools and bolts because they are only subjected to tensile load, ITH Stretch Method is free of friction and torsional stresses

- Robust tool design: ideal for use on-site

- Easy and worksafe operation loosening of bolted connections by only stretching the bolt in an axial direction, which is especially useful to loosen highly stressed bolts. Compared to torquing methods there is no need to apply high forces onto the bolt in one moment (impulse) to overcome the loosening moment (resistance due to friction)

ITH Bolt Tensioning Cylinders can be used universally for bolts from M16 (5/8") and up. A high percentage is designed to customer's demands.

Due to their design and working principle the Bolt Tensioning Cylinders are particularly useful for

- Bolted joints with are only accessible in axial direction due to their installation position

- Ideal for applications where stainless steel is used because there is no risk of galling threads

- Bolt connections (e.g. gas turbines) which are used under high temperatures can be demounted without any demolition even after long time

- Foundation bolts: For safety reasons long foundation bolts should not be applied with bending or torsion forces, which make it an ideal application for ITH Bolt Tensioning Cylinders

Hydraulic Bolt Tensioning Cylinder management software and test stand

-

Automatic control and easy documentation with the digital documentation system PD / PSD for ITH Bolt Tensioning Cylinders.

-

Testing Bolt Tensioning Cylinders on-site: Automatic test procedure and digital documentation via industry-PC.

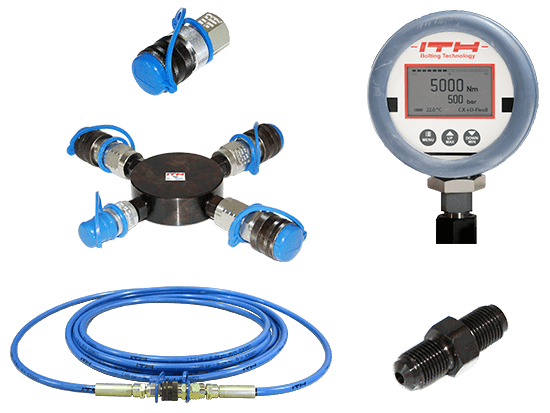

Couplings, destributors, hoselines, test gauges for bolt tensioners

-

Hydraulic equipment: high-pressure hoses | couplings | nipples | coupling distributors | test gauges.

Contact your local person in charge

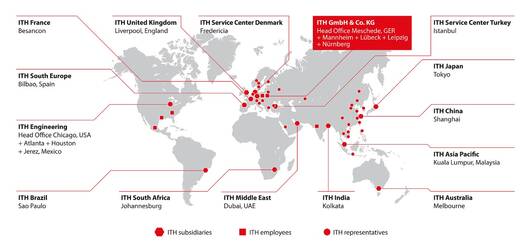

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.