Project Engineering

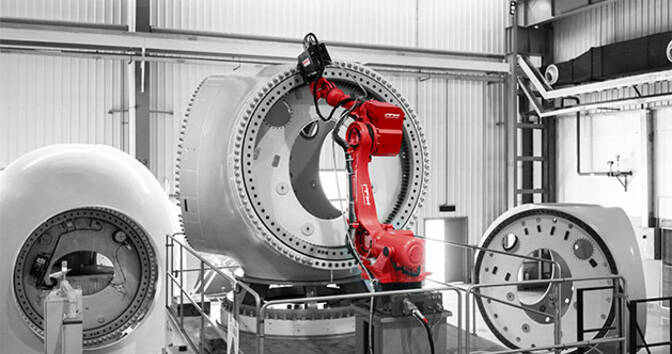

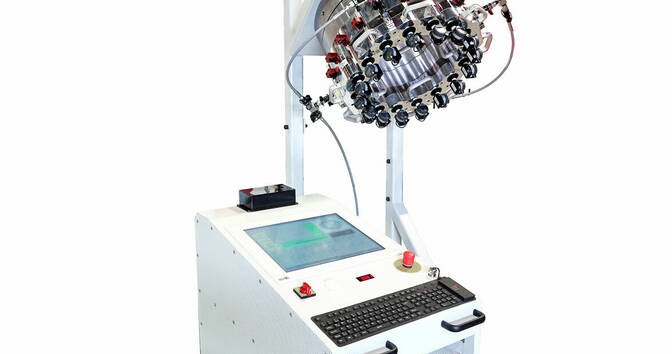

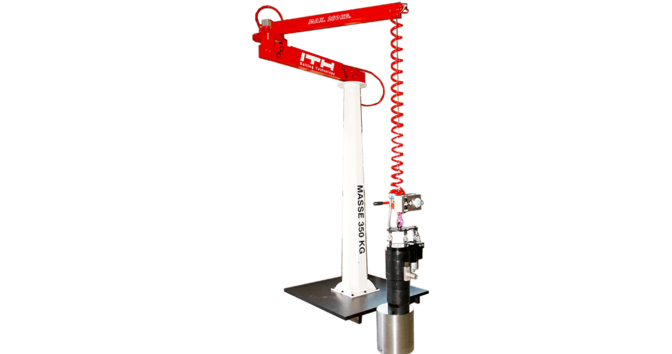

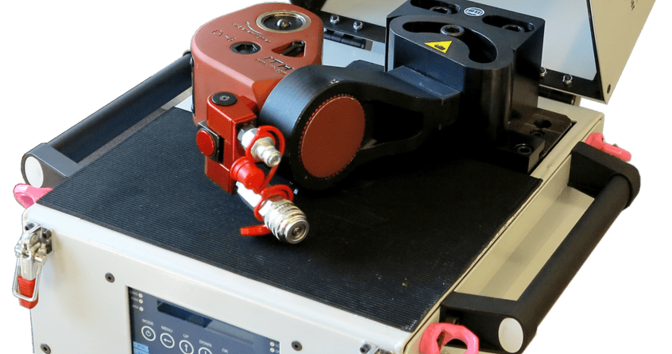

ITH project engineering: implementing customer specific solutions in bolting technology

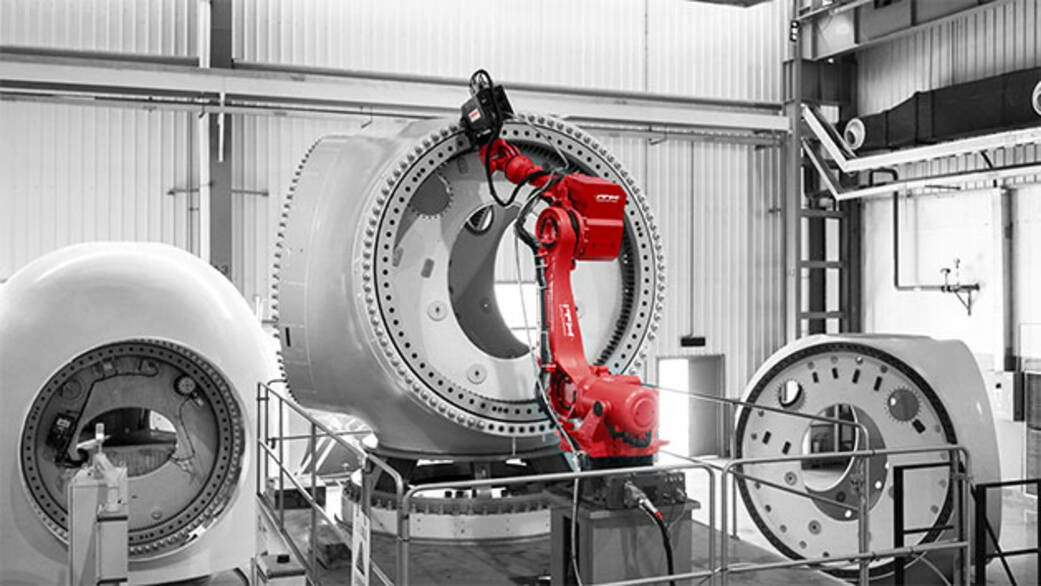

Since the beginnings in 1979 ITH has successfully implemented numerous individual solutions for business partners and whole industries. For example: transport and lifting devices, automation solutions, lifting or extraction tools, digital documentation, management systems and many more. Those innovative devices have led to significant time and cost reductions for customers because they provide higher efficiency. They speed up processes and make bolting jobs easier and safer.

Bolting project process

Here is a sample process of ITH project engineering:

- Contact

to business partner: competent, objective consultation - Analysis

of the bolted joint / the task / the application - Development of a solution

by the ITH design department - Result

The best technical and most cost effective solution for customers.

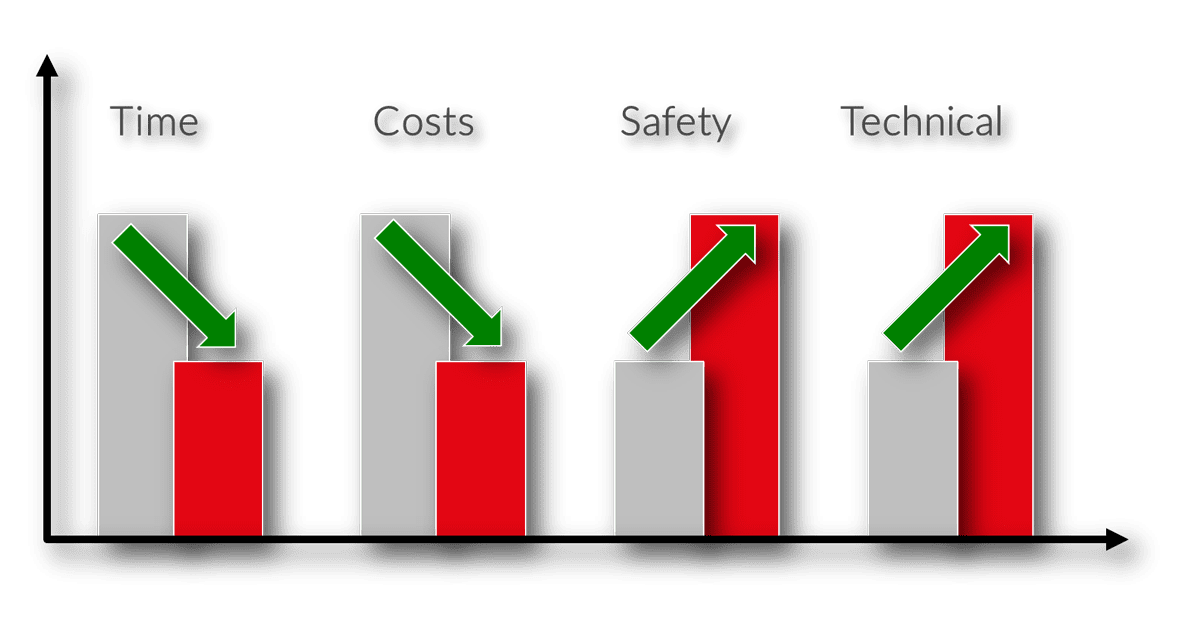

Advantages of ITH project engineering

Optimized bolted joint design, innovative bolting tools, or customer-specific solutions lead to cost reductions.

The most cost saving options are achieved by:

- Time saving

(faster bolting procedures, less total assembly time and/or maintenance procedures, reduced costly downtimes of machinery) - Optimized flange design by small alpha-a factors up to 1.1

By achieving small alpha-a factors up to 1.1 , ITH bolting solutions offer:

a.) higher pre-tensioning forces when the bolt sizes and flange dimensions are unchanged

b.) unchanged pre-tensioning forces with smaller bolt sizes and flange dimensions (example: substitution of M72 by M64 with a higher bolt spacing t) which leads to significant cost reductions - Higher working safety

with patented ITH safety features and easier handling - Customer specific solutions

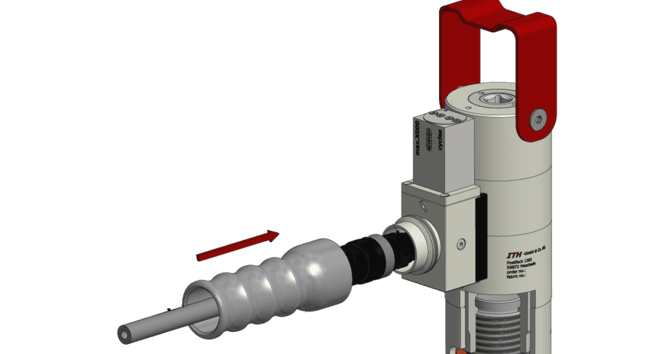

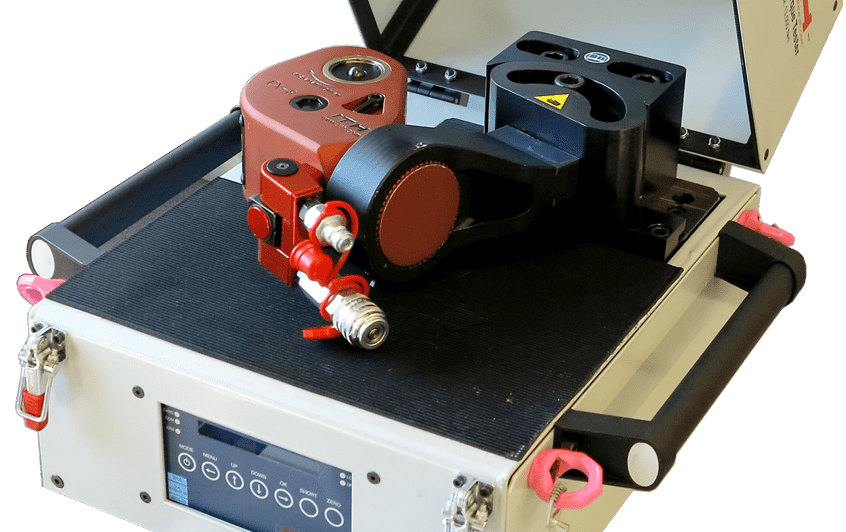

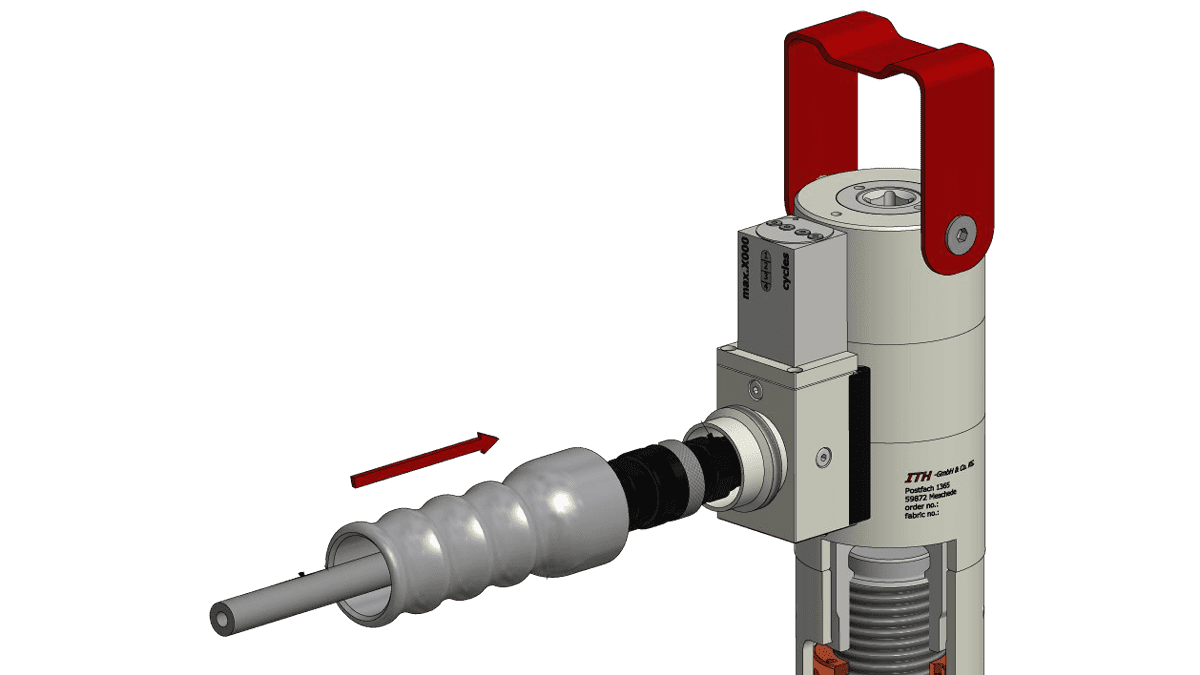

Specific bolting tools like lifting/extracting /spreading devices, hydraulic jacks, automated solutions, or customer-specific management software

Examples of ITH project engineering

Synergy effects from a whole system supplier

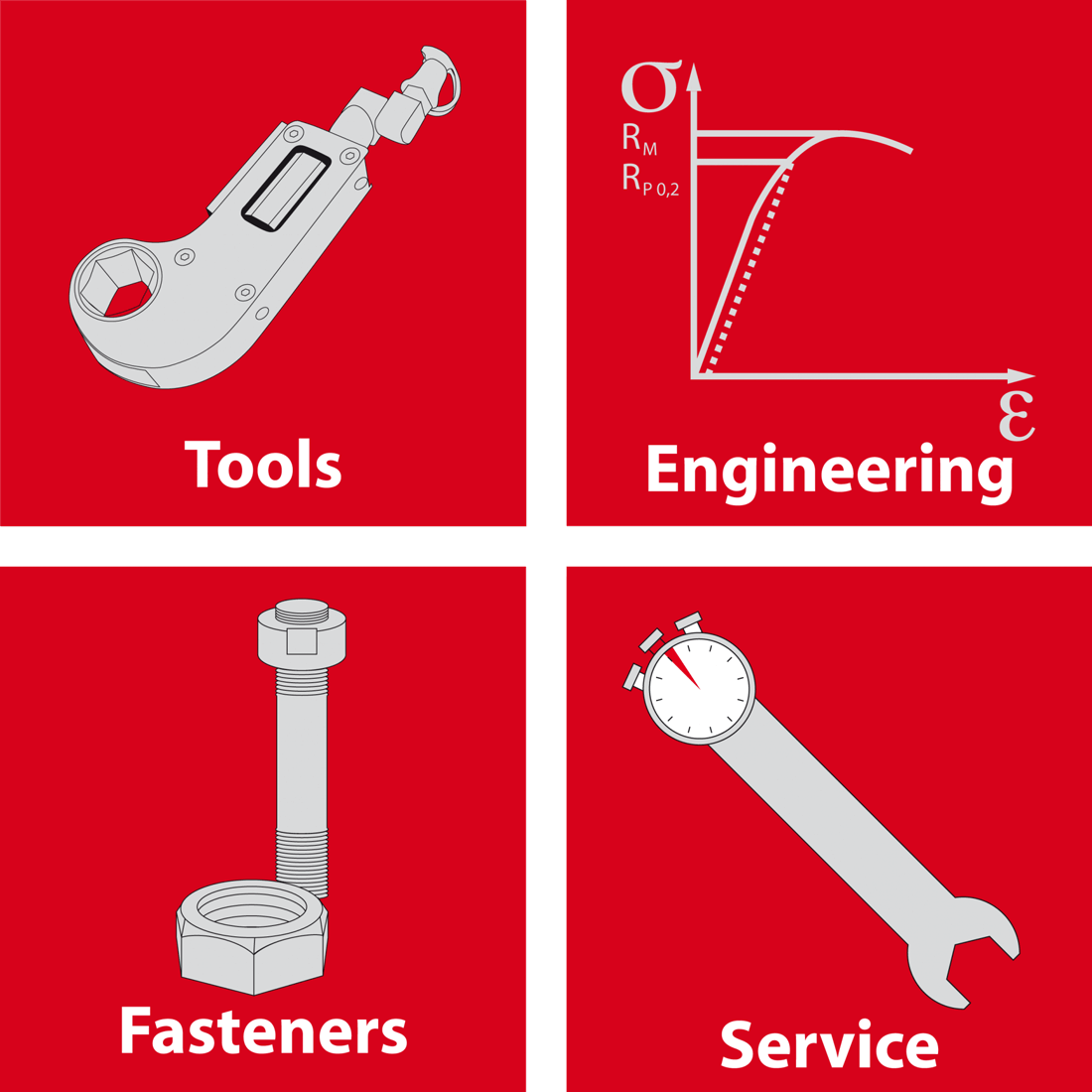

The technical and economical efficiency of a bolted connection depend on 4 major factors:

- Design elements

- Fasteners

- Bolting method (tensioning, torqueing, others)

- Assembly procedure

Being a whole system supplier only ITH Bolting Technology analyzes the whole picture. We have the capacity to configure the factors among each other for the best technical and most cost-effective solution for our business partners. One factor affects others positively: That is what we call technically efficient.

Overview all ITH industry solutions

ITH has developed several solutions for all industries like

- power generation inustries

- maritime and offshore

- machines and more

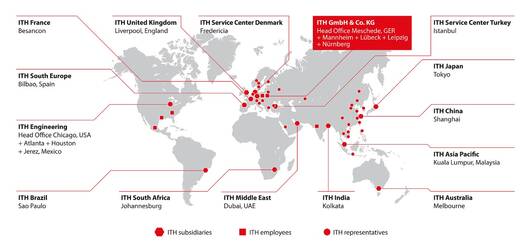

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Electric, pneumatic and battery powered torque wrenches which operate due to the torque method respectively to the torque-angle method.

-

Overview of all types of hydraulic torque wrenches, working due to the torque method or torque-angle method.