Bolted joints for oil and gas industry - bolting tools and bolting solutions

Industrial bolted joints - Bolting tools and bolting solutions for specific industries

ITH provides a large spectrum of bolting tools and solutions for bolted joints in the oil and gas industry - both for on and offshore applications. These bolting solutions include:

- Assembly and disassembly of flanges according to ANSI-standard or ASME-standard

- Flange cover applications

- Bolted joints on high pressure pumps, pump stations, metering pumps

- Heat exchangers

- High pressure vessels

ITH offers air-powered (pneumatic) bolting tools for the oil and gas industry to meet their requirements. These bolting tools include:

- Pneumatic, hydraulic pump series Aero-MAX for bolt tensioning cylinders

- Hydraulic torque wrenches and the corresponding pneumatic hydraulic pump series Aero-DAX

- Pneumatic nut runners type PDS

Find an overview of examples of bolted joints and bolting tools in the oil and gas sector below. Contact us for more information or with questions regarding your individual bolted joint.

Oil and gas bolt connections: tension and torque tools

|

Application / bolted joints |

ITH bolting tools, solutions and equipment |

|---|---|

|

ANSI flanges |

|

|

ASME flanges |

|

|

Heat exchanger bolt connections |

|

|

Movement of flange covers |

|

|

All further bolting applications bigger than M16 (5/8'') |

Browse our tension and torque tools overview to overview all solutions or contact us. We would be happy to give technical advise. |

Bolted joints on pumps and compressors

In the oil and gas industry often used components are high pressure units, pump stations or turbines. Find more information on bolting tools for bolted joints of pumps or tubines within our industry solutions.

ITH Multi-Tensioning for the ANSI-flanges

Tightening ANSI-flange bolt connections: It is recommended to tighten several bolts at the same time to significantly reduce the risk of leakage.

ITH Multi-Tensioning

By using the ITH-Multi Tensioning method, multiple bolt tensioning cylinders are used simultaneously by connecting them to one hydraulic unit (connected in series or in parallel). All bolts are tightened simultaneously and the required pretensioning forces are generated evenly. This leads to precise results: Using ITH-Multi Tensioning repeatable pre-tensioning force within a tolerance level of ±2% can be reached.

Advantages tightening bolts with the ITH Multi-Tensioning:

Using the ITH Multi-Tensioning method leads to:

- Significantly reduced risk of leakage

- Increased lifetime of flanges, seals, and fasteners

- Fast working procedures

- Reduced downtimes of the complete application which saves costs

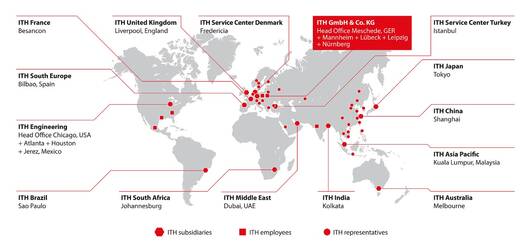

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

Bolted joints in the oil and gas industry: related information

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Overview of all types of hydraulic torque wrenches, working due to the torque method or torque-angle method.

-

Electric, pneumatic and battery powered torque wrenches which operate due to the torque method respectively to the torque-angle method.