ITH scope of industrial fasteners

The scope of ITH fasteners for industrial bolt connections comprises:

- Thread sizes: M20 (3/4") to W510 (510 mm/20,078”) and larger

- Surface treatments: Galvanic processes, zinc lamellar coating, hot dip galvanizing, (PTFE) fluorocarbon coatings, and many more.

- Materials: Tempering-, High-Temperature- ,Extreme High-Temperature- , Cryogenic-, Stainless Steels, and many more.

- Products: Hexagonal bolts, Hexagon socket bolts (Allen bolts), Expansion bolts, ITH stud bolts, ITH washers, hexagonal nuts, and round nuts.

Choosing and designing fasteners

ITH fasteners are used in all industry sectors for example on highly stressed roller bearings on wind turbines or on gas and steam turbines. As ITH manufactures both the fasteners and matching bolting tools for the installation, bolted joints are often designed by ITH (system supplier).

Fasteners are designed due to their application environment and due to the type of stresses (static, dynamic, thermal) they are submitted with.

One of the fundamental guidelines to design highly stressed bolted joints is the German guideline VDI 2230. The following examples of individual fastening elements are intended to offer an overview. Contact us for a free technical consultation - we are pleased to advise you and help you designing your bolted joint

Overview ITH standard fasteners

Advantage

- standardized and commonly used

- economic for short clamping lengths and small dimensions

Disadvantages

- concentration of stresses in head

- danger of cracking through upset head

- limited angularity of thread axis to underlying surface

- procurement of special materials

- use not feasible at high bending loads

Advantage

- use in radially restricted spaces

Disadvantage

- concentration of stresses in head

- danger of cracking through upset head

- limited angularity of thread axis to underlying surface

- procurement of special materials

- use not feasible at high bending loads

Advantage

- use in thermally stressed joints

- reverse bending stresses

- dynamic stresses

- procurement possible for special materials

Disadvantage

- complex production due to expansion shaft

are produced from thread-size M20 (3/4") The threads can be rolled up to M120 (5"). Stud bolts have the following advantages:

- low-cost production as shaft diameter equals rolling diameter

- low stress concentration for optimum layout

- easy procurement and production with special materials

To achieve an economical and technically acceptable joint, ITH recommends M39 hexagonal nuts to EN ISO 4032. From thread size M42, ITH advises using round nuts of type RMZ or RMS.

are produced in standard sizes for threads of M20 (3/4") to M100 (4").

The nuts have the following advantages:

- high plane parallelism

- high bending strength therefore lower loss of pre-tensioning force

- easy procurement and manufacture with special materials

all ITH washers are dimensionally matched to ITH bolt-tensioning cylinders

Used material for bolts, nuts and washers

Following choice of standard material specifications for fasteners are only exemplary - fasteners are often manufactured out of special material specification. Contact us for more information

|

Abbreviations |

Material no. |

UNS-No. USA |

ASTM/AISI/SAE USA |

|---|---|---|---|

|

42CrMo4 |

1.7225 |

H41400 |

A304/AISI 4140H / SAE J775/1268 |

|

32CrMo12 |

1.7361 |

- |

- |

|

34CrNiMo6 |

1.6582 |

- |

- |

|

30CrNiMo8 |

1.6580 |

- |

- |

|

50CrV4 |

1.8159 |

H61500 |

A304/AISI 6150H /SAEJ1268 |

|

Abbreviations |

Werkstoff- No. |

UNS-No. USA |

ASTM/AISI/SAE USA |

|---|---|---|---|

|

24CrMo5 |

1.7258 |

H41300 |

A304/AISI 4130H / SAE J1268 |

|

21CrMoV57 |

1.7709 |

- |

- |

|

40 CrMoV47 |

1.7711 |

- |

A193 Gr B16 |

|

X22 CrMoV12-1 |

1.4923 |

S42200 |

A126/565/ AISI 422 /SAE J467/775 |

|

X19CrMoVNbN11-1 |

1.4913 |

- |

- |

|

X8CrNiMoBNb1616 |

1.4986 |

- |

- |

|

NiCr20TiAl Alloy 80 A |

1.4952 |

NO7080 |

B637/ SAE J467 |

|

Abbreviations |

Werkstoff- No. |

UNS-No. USA |

ASTM/AISI/SAE USA |

|---|---|---|---|

|

26CrMo4 |

1.7258 |

H41300 |

A304/AISI 4130H / SAE J1268 |

|

X6CrNiTi18-10 |

1.4541 |

S32100 |

A128/193/194/213/ 240/249/269/276/312 376/479/ (weiter s. Werkstoff S32100 AISI 321/SAE J405/412/467) |

|

X5CrMnNiN18-9 |

1.6909 |

S21900 |

A269/276/312/314/ 473/580/813/ 814 |

|

Abbreviations |

Werkstoff- No. |

UNS-No. USA |

ASTM/AISI/SAE USA |

|---|---|---|---|

|

X17CrNi16-2 |

1.4057 |

S43100 |

A176/276/314/473/479/493/ 511/579/580/593/594/AISI 431 / SAE J412 |

|

X5 CrNi18-10 |

1.4301 |

S30400 |

A182/194/213/240/249/312/ 320/336/358/368/376/403/ 409/430/473/497/492/493/ 511/554/580/632/666/688/ 774/793/813/814/851/908/ 943/965/988. AISI 304 SAE J405/412/467 |

|

X6 CrNiTi 18-10 |

1.4541 |

S32100 |

A182/193/194/213/240/249/ 269/276/312/313/320/336/ 358/376/403/409/430/473/ 479/493/511/554/580/632/ 774/778/813/814/943/965/ AISI 321 / SAE J405/412/467 |

|

Abbreviations |

Werkstoff- No. |

UNS-No. USA |

ASTM/AISI/SAE USA |

|---|---|---|---|

|

24CrAlloy 718 NiCr19NbMoMo5 |

2.4668 |

N07718 |

B637/ B670/ SAEJ467 |

|

Alloy X-750 NiCr15Fe7TiAl |

2.4669 |

NO7750 |

B637/ SAEJ467 |

|

Alloy 80 A NiCr20TiAl |

2.4952/ 2.4631 |

NO7080 |

B637/ SAEJ467 |

Dimensions and Mechanical Production

The high standard of quality and the large production facilities make it possible to manufacture special bolts in various sizes and tolerance classes. ITH's supply range begins with thread size M20 (3/4"). The largest thread manufactured to date by ITH was W510 (510 mm / 20").

Mechanical production

The mechanical machining of the fastening elements is carried out on state-of-the-art CNC machines with driven tools. The threads (up to M120/5") are made by ITH using the cold-rolling process. Depending on size and material, the thread is cold-rolled by the continuous or recessing process. Through cold rolling, the root area of the thread is strengthened. This increases the yield strength of the bolt material in edge areas of thread flank and core fillet. At the same time, the internal compressive stresses are created which later overlap with the tensile stresses, thereby creating an overall tensile state (especially in the edge zones of the thread root), which has a positive effect on the life of the bolt.

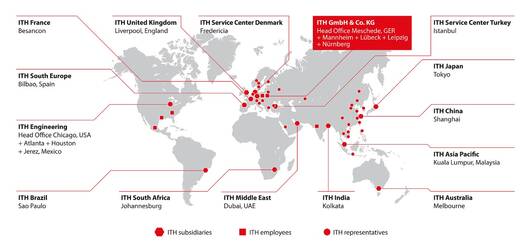

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.