Bolted joints for gas and steam turbines: ITH leads the market

Bolted joints for gas and steam turbines: ITH leads the market

In 1979 ITH introduced the ITH Stretch-Method on steam turbines successfully. This was followed by the implementation on gas turbines shortly after. Today more than 1,600 gas and steam turbines worldwide use the ITH Stretch-Method - the leading procedure to tighten and loosen bolted joints in turbine construction.

Joint design on turbines by ITH

During the introduction process the design of the bolted joints was made by ITH. Joint design, fastener specifications and bolting tools (Bolt Tensioning Cylinders) were configured together which guaranteed the best technical and economic bolting solution.

Advantages of the ITH Stretch-Method on turbines:

Time saving

During the regular maintenance intervals the turbine casings are opened and closed. More than 2000 successful maintenance jobs prove that time reductions up to two days can be achieved using the ITH Stretch-Method in comparison to the torquing or heating method.

Less material costs

Due to thermal stress during the turbine's operation (up to 600° C), loosening the bolted joints can be challenging. The torque system requires extremely high forces to loosen the bolted connection which increases the risk of damage to tools, fasteners, and the turbine casing.

The ITH Stretch-Method operates free of friction and torsion by applying coltrolled and even pressure. Bolts on turbines can be loosened much easier. The risk of damage decreases significantly. Less damage translates to less costs.

Another benefit of the ITH Stretch-Method: Bolts do not require an internally machined hole as they do with the thermal method.

Bolted joints on turbines: Examplary hadraulic bolt tensioning tools and solutions

|

Application / Bolted joint |

ITH-bolting tools, solutions and equipment |

|---|---|

|

Casing bolt connections

|

|

|

Rotor bolt connections |

|

|

Generator bolt connections |

|

|

Foundation bolts |

|

|

General bolt connections |

|

|

Main shaft |

|

|

All further bolting applications bigger than M16 (5/8'') |

Browse our tension and torque tools overview to overview all solutions or contact us. We would be happy to give technical advise. |

Further projects on gas- and steam turbines

Beyond these applications, ITH has supplied tools for numerous customer specific projects for gas and steam turbine manufactures. For example:

- Large scale bolt tensioning cylinder (from M160 to M800)

- Lifting devices

- Specially designed bolt tensioning cylinders with a conical head design for the inner CDC - housing

- Design of the bolted joints

- Retrofit projects: ITH converted many turbines from conventional methods to the innovative ITH Stretch-Method with engineering, hardware and on site bolting service.

- The ITH service staff has performed more than 2000 bolting jobs on gas and steam turbines worldwide. Our team has proven to work safely, reliably and fast.

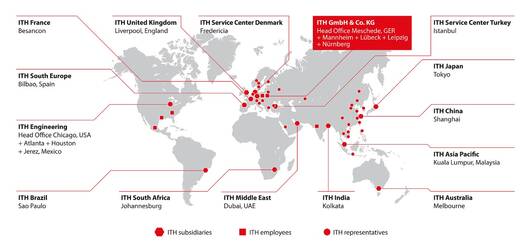

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

ITH solutions for industrial applications: Related information

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Overview of all types of hydraulic torque wrenches, working due to the torque method or torque-angle method.

-

Electric, pneumatic and battery powered torque wrenches which operate due to the torque method respectively to the torque-angle method.