Bolted joints in steel mills - bolting tools and bolting equipment

Bolted joints in steel mills - bolting tools and bolting equipment

Find an overview of examples of bolted joints and bolting tools for steel mills below. Contact us for more information or with questions regarding your individual bolted joint.

Bolted joints in steel mills

|

Applications / bolted joints |

Bolting tools, solutions and equipment |

|---|---|

|

Ladle turret |

|

|

Steel structures |

|

|

Foundation bolts |

|

|

Segments (casting plant) |

|

|

Roll stand connection |

|

|

All further bolting applications bigger than M16 (5/8'') |

Browse our tension and torque tools overview to overview all solutions or contact us. We would be happy to give technical advise. |

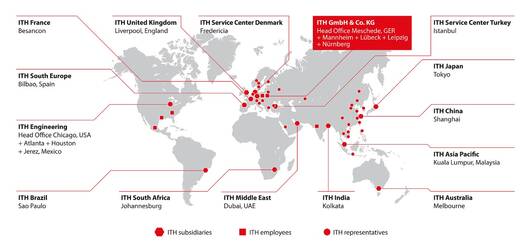

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

ITH solutions for bolted joints in steel mills: related information

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Overview of all types of hydraulic torque wrenches, working due to the torque method or torque-angle method.

-

Electric, pneumatic and battery powered torque wrenches which operate due to the torque method respectively to the torque-angle method.