Hydraulic Bolt Tensioning Cylinder type ESX, single-stage, with quick exchange

Innovative ITH Quick Exchange

- The innovative ITH quick exchange mechanism gives the series its name.

- The quick exchange enables a fast interchange of the change bushings, which makes the ESX suitable for different thread profiles and bolt diameters.

- No extra tool required for the interchange.

Designed to match flange standards

- Very compact tool dimensions and preloads are designed to match common flange standards such as:

ASME

ANSI

MSS

DIN EN ISO

VDI

National standards

and more

- Optimized design enable the ESX for ITH Multi-tensioning – even on smaller flange dimensions. By simultaneous tightening of multiple bolts the sealing of flanges receive an even and precise load distribution. This reduces the risk of leakages significantly.

Features:

- With automatic piston return for faster bolting procedures

Patented ITH Safety Concept:

- Patented ITH Cycle Counter, Safety.

Tool data

When tightening bolts on a flange it is recommended to tighten multiple bolts simultaneously. This reduces the risk of leakages significantly.

During ITH Multi-tensioning multiple Bolt Tensioning Cylinders (for 25%, 50%, 70% or 100% of all bolted joints on a flange) are interconnected to one hydraulic circuit and one hydraulic pump unit.

The hydraulic circuit can be arranged parallel or in series. Therefore the preload forces are transferred evenly to the bolted connection and the sealing receives an even load distribution.

The innovative ITH Quick Exchange mechanism gives the ESX-series its name.

By turning the ringelemente can be unlocked which enables to exchange the change bushing easily. No extra tool is required which simplifies and accelerates the interchange process. Markings for “locked” and “unlocked” on the ring element give users clear orientation.

By interchanging change bushings (the part which contacts the thread of the bolt) a Bolt Tensioning Cylinder can used on different thread profiles and bolt dimensions. This leads to more flexibility and less costs for users.

In order to use given material most efficient, some very compact flange designs offer only a small distance from the bolt center to the pipe. Flanges with bigger necks can reduce the space given for bolting tools.

ITH Bolt Tensioning Cylinders type ESX are designed to match these requirements by reduced outer diameters and reduced supports. Design parameters and also preload forces can be designed to match the specifications from common flange standards.

Change bushing module

- One hydraulic ITH Bolt Tensioning Cylinder can be equipped with different change bushings to match different thread profiles or bolt diameters.

- The flexible ring element of ITH Bolt Tensioning Cylinders type ESX fixes the change bushing during operation (ITH Quick Exchange).

- Square drives on top enable change bushings to be turned down by nut runners to accelerate the bolting process.

- Change bushings can be designed with a vertical bore hole to be ready for length change measurement (ITH PD / PSD system). The length change of a bolt during bolting is an indirect method to measure the applied preload force.

- Red control mark on top of the change bushing indicates maximum hub and therefore increases safety.

Support module

- One hydraulic ITH Bolt Tensioning Cylinder can be equipped with different support modules to match different nut and washer designs.

Supports can be designed to match all common bolt-nut-washer configurations like for example:

DIN ISO standards

Heaby hex nuts

HV-standard

ITH Roundnuts RMS or RMZ, IHF Roundnuts

Hexagonal nut designs, roundnuts with radial bore holes, custom designed nuts and washers.

The control notch on the bottom of the support offers to control visually, if the nut has contact to the surface.

Turning sleeve

- The turning sleeve is the part of the support module which encloses the nut radially.

- Spring-loaded turning sleeves automatically center up onto the nut which leads to a faster installation of the Bolt Tensioning Cylinder on the bolted joint.

- When using nuts with radial boreholes, a turning sleeve is not required. The nut is turned down by the use of an adjusting stick though an adjusting window.

Direct geardrive

- Accelerates and offers torque-controlled turning down nuts by use of a hand torque wrench (available square drives ¼” to ½”)

Hydraulic connector module

- Vertical or horizontal

- With or without ITH patented cycle counter

- With or without ITH Multi-tensioning connector, recommended for flange applications

- With or without ITH patented protection cap

Carrying device

- Strong and flexible carrying strap for easy handling. Steel bar version optionally.

Optional features as in the picture:

- ITH patented cycle counter: Counts and displays pressure cycles and offers easy information regarding tool maintenance.

- NIOX coating: Optional Nickel-Chromium coating offers extra protection from corrosion.

- ITH patented protection cap with handle: Protects hydraulic connector, increases ergonomic handling and work safety.

- Support design for round nuts with radial boreholes.

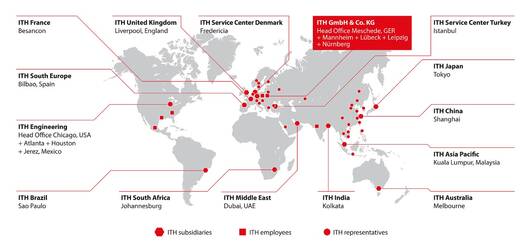

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

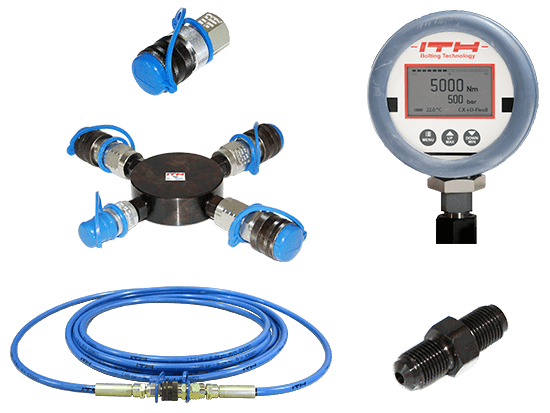

Bolt Tensioning Cylinder type ESX: related products

-

Hydraulic equipment: high-pressure hoses | couplings | nipples | coupling distributors | test gauges.

-

Testing Bolt Tensioning Cylinders on-site: Automatic test procedure and digital documentation via industry-PC.

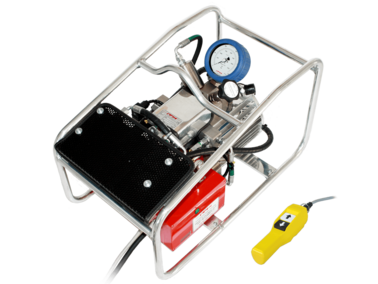

-

Electric, pneumatic, manual and battery-powered high pressure hydraulic pump series