Multi-stage design: Tall & slim design for vertically open but limited radial clearance applications

Multi-stage design

Optional: Simultanous tensioning of multiple bolted joints with ITH Multi-tensioning

Hydraulic Bolt Tensioning Cylinder type MS, multi-staged

Slim design

- For vertically open but limited radial clearance applications

ITH safety concept

- Patented safety features cycle counter, safety handle, and safety fracture device

Standard and large-scale

- For bolted connections from M16 (5/8") and up

Technical data, application examples, features and function

Clearance: radially limited, vertically open

ITH Bolt Tensioning Cylinder type MS with NIOX surface coating, patented safety handle and cycle counter is used on the horizontal casing flange on a 250 MW gas turbine. For this casing ITH round nuts are used. The nuts are tightened down using a turning pin through the support opening at the turning sleeve.

To match specific requirements of applications ITH is able to customize the design. In this case the support - the lower part of the tool - is chamfered.

ITH Multi-Tensioning with Bolt Tensioning Cylinder type MSK

As an option you can use a number of cylinders at the same time (ITH Multi-Tensioning), like here at the rotor blade to hub connection during the erection of a wind turbine (M24, 10.9).

With ITH Multi-Tensioning you can use a number of Bolt Tensioning Cylinders together to tension bolts simultaneously (pictured: specific Multi-Tensioning hydraulic coupling at the tool). All Bolt Tensioning Cylinders will then be operated by a single hydraulic pump.

With the optional test gauge the applied pressure of the complete hydraulic circuit can be checked.

ITH Multi-Tensioning with Bolt Tensioning Cylinder type MSK

The bolt connections (bolt size M24 [7/8''], bolt quality 10.9) between hub and rotor blade are tightened during the erection of the 850 kW wind turbine when it is lying on the ground.

The simultaneous pre-tensioning of the bolts (ITH Multi-Tensioning) allows a uniform and precise application of the pre-tensioning force. This improves the quality and the durability of a bolt connection significantly.

ITH is the standard for tensioning at slewing bearings

In 1980 ITH successfully introduced the ITH Stretch-Method as the leading method to tighten slewing bearings. Currently, ITH Bolt Tensioning Cylinders are the most commonly used tools for tensioning of slewing bearingings.

Here you can see an ITH tensioner on the bolts of a double excenter slewing bearing of a railroad crane (bolt dimensions M48 [7/8"], bolt quality 10.9, tensioning force 1,220 kN).

During the tensioning of the slewing bearing the bolt connections have to be evenly pre-tensioned. If not then the risk of galling between the ring element and the castors is really high. The repeatability of the tensioning forces is within a tolerance of ± 2.5 % . Therefore the ITH bolt tensioning cylinders are precise and deliver an even result which guarantees a sustainable bolt connection.

The ITH Bolt Tensioning Cylinder type MS 42 - 490 (tensioning force 490 kN) is used at the horizontal flange M42 (1 5/8") at a gas turbine. The radius of the tool has been customized to the notches that are at the turbine.

In this case the round nuts with radial wholes are tightened and loosened through a small window at the support by using the turning pin.

The M36 (1 3/8") bolt connection at a ladle turret in a steel mill is pre-tensioned with the ITH BTC type MS 36 -670. The Bolt Tensioning Cylinder configuration here is: hydraulic block with cycle counter, direct gear drive, carrying strap, burnished surface (blackened), ITH high-pressure coupling with safety spring.

With the delivered fasteners from ITH (ITH Round Nut RMS, hexagon size) a better αA-value of 1.1 is achieved. The smaller the αA-factor, the more efficient, compact and precise you can design bolted connections.

ITH bolt tensioning cylinders type MSK are used at the inner tower flange of a wind turbine. The bolt tensioner allows for fast, repeatable and precise tensioning of the bolts.

Through the chamfering of the support of the tools, the slim radius of the bolt tensioning cylinder, and the use of IHF fastener system (IHF-Stretch-Bolt and IHF Round nut RMZ) you can achieve

1. reduced the center distance between the bolt and the inner wall

2. The screw space at the ring flange (number of bolts) can be minimized

Due to these factors you can reduce the flange thickness (amount of steel), this leads to a cost advantage at the wind turbine with the solutions of ITH Bolting Technology.

A typical application for Bolt Tensioning Cylinders type MS: radially limited, vertically open clearances

By the slim outer diameter (compared to the relative pre-tensioning force) the Bolt Tensioning Cylinder type MS 45 - 1,200 can tension bolts (M45 [1 3/4"], bolt quality 12.9) at the tower connection of a crane with no problem in fast and easy way.

Optional Nickel-Chromium coating which prevents components from corrosion. The standard Bolt Tensioning Cylinders are protected by a burnished surface.

The innovative ITH safety concept for Bolt Tensioning Cylinders includes the patented cycle counter, the patented protection cap at the handle and the patented safety fracture device.

- Counts each pressure cycle of the tool and clearly displays the current cycle

- Offers an easy way to track working procedures for users

- Improved tool management by tracking cycles for maintenance intervals and service, which promotes safe working conditions

Increasing the working speed: The integrated automatic piston return pushes the piston back to its end position when the hydraulic pressure is released (Change bushing positions even with the cylinder cover).

One Bolt Tensioning Cylinder can be equipped with several change bushings (for different bolt dimensions) which is flexible and cost-effective.

Accelerating the assembly: Setting up the Bolt Tensioning Cylinder the inside turning sleeve automatically adjusts and contains the nut.

The control notch on the foot of the support offers an easy visual inspection to check, if the nut lays even with the surface before pressurizing the BTC.

Optional: By an integrated measurement hole throughout the change bushing Bolt Tensioning Cylinders type MS are ready for optional digital documentation system (PSD / PD System). With an attachable digital measurement gauge the realized bolt elongation of each bolt can be measured. This allows to compare the realized force of each bolt connection among a series of bolting operations.

The heavy duty and direct gear drive (1/2" or 1/4") drives the inside turning sleeve which encloses the nut. Thereby the nut can be turned easily in the direction of rotation with a hand ratchet.

Strong and flexible for an easy handling. For the bigger Bolt Tensioning Cylinder dimensions ITH offers pneumatic spring balancers for an easy transport.

Various hydraulic connection configurations can be chosen due to application requirements:

- Standard: horizontal with cycle counter

- Multi-tensioning hydraulic connection: male and female couplers on the hydraulic block, with or without cycle counter

- Without cycle counter: horizontal or vertical.

All horizontal connections are compatible with optional safety handle (on the left).

Design

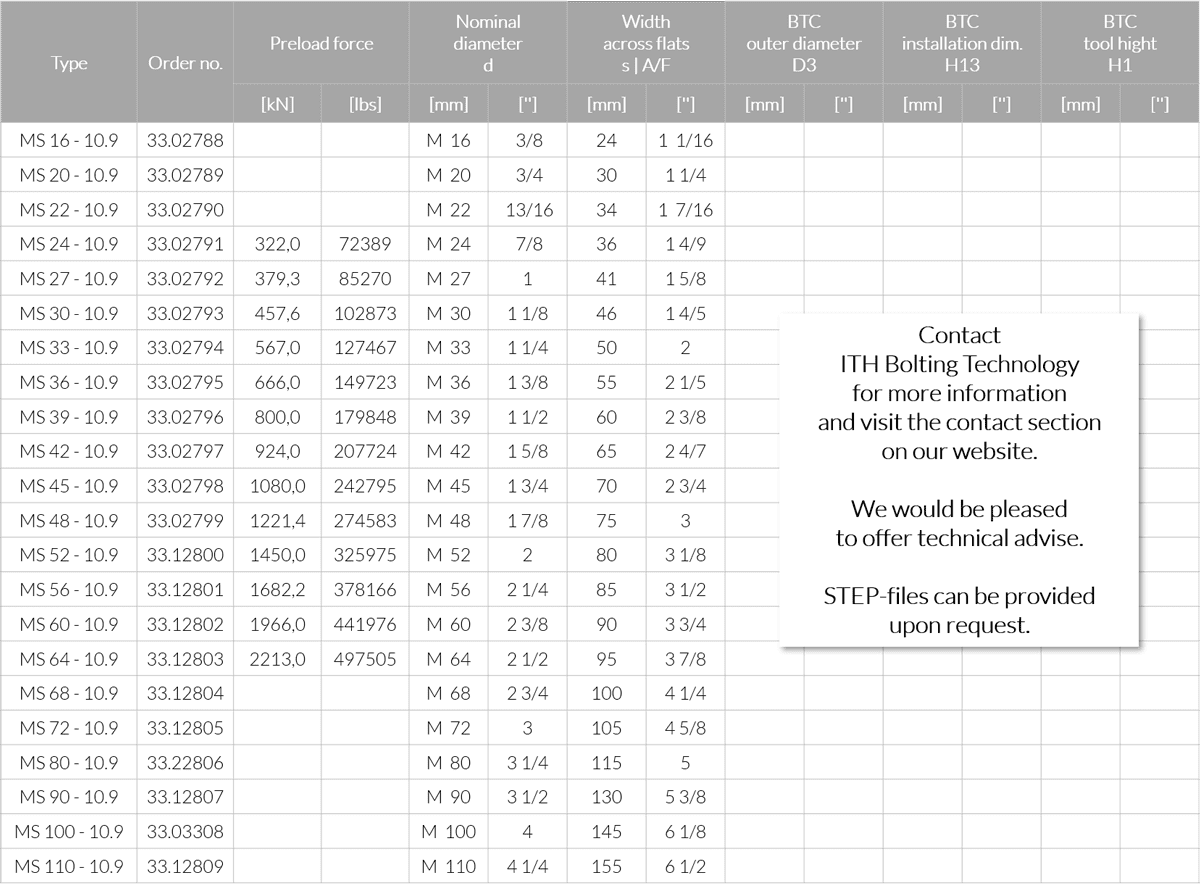

Type MS (Multi-stage): Tall & slim design for vertically open but limited radial clearance applications

Standard scope

- design for bolt quality 10.9: M 16 to M 110

- Please contact us for bolt qualities 5.6, 6.8, 8.8 or 12.9 or customer specific designs and dimensions.

Thread projection

The minimum required thread projection of the bolt above the nut: 1,0 x d of the bolt (depending on the preload force). If there is not enough thread projection ITH recommends the use of ITH tension nuts.

The BTC can be used for the following fastener configurations

Hexagon nuts

- ISO 4032: Hexagon nuts (former DIN 934)

- DIN 2510-5: Hexagon nuts

- EN 14399-4: High strength pre tension able bolt connections for the steel constructions (former DIN 6915)

- Heavy hex nuts

- Hexagon nuts according to customer designs

Round nuts:

- Round nuts with radial hole

- Round nut with center holes

- ITH Round nuts RMS /RMZ

- IHF Round nuts

ITH multi-stage Bolt Tensioning Cylinder type MS for bolt quality 10.9, available standard from M16 (5/8'') up to M110 (4 1/4'').

Contact us for:

- bolt qualities 5.6, 6.8, 8.8 or 12.9

- further technical data

- special customized designs

- a free of charge technical consultation

We would be pleased to give advise.

Technical modifications and changes are reserved. Feel free to contact us for an individual design or further information.

Product description of ITH Bolt Tensioning Cylinder type MS

Hydraulic, friction- and tension-free tightening with the ITH Stretch-Method

By using the ITH Stretch-Method you will achieve a preload force with a small tolerance band of only ± 2.0 %.

The requirement for the application of the ITH Stretch Method is the thread projection of 1.0 x d of the bolt. (Depending on the pre-load force, d = thread diameter). If there is not enough thread projection ITH recommends to use ITH tension nuts.

The bolting process

The bolt tensioning cylinder is threaded onto the bolt by use of a hand torque wrench or a battery nut runner.

The calculated pressure is generated by an ITH high-pressure pump. This creates a torsion and friction free elongation of the bolt. The hydraulic pressure at the pump is directly proportional to the pre-load force of the bolt tensioning cylinder that is applied at the bolt.

When the pressure has been achieved the nut is tightened down by use of a hand torque wrench for controlled torque output.

Advantages of the ITH Stretch Method in comparison to the traditional method

In the conventional system (torque value method) the pre-load force is applied by a mounting process which shows torsion- and friction stresses at the nut and the bolt by torqueing them together. During this process the torqueing tool has to work against to moment of thread pitch and the friction at the thread on both laydown surfaces.

At the assembling process the thread friction, the head friction- and moment of thread pitch come all together. The thread- and moment of thread pitch can have a value of 90% of the final torque value.

The assembly pre load shows a high deviation based on the deviation of the friction values of the thread and under the head of the volt. The friction value by friction class B shows a deviation from 0,08 to 0,16, by these value the preload force can deviate of about 100%.

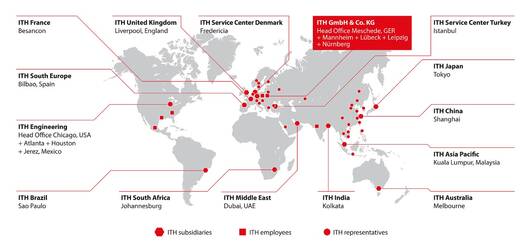

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

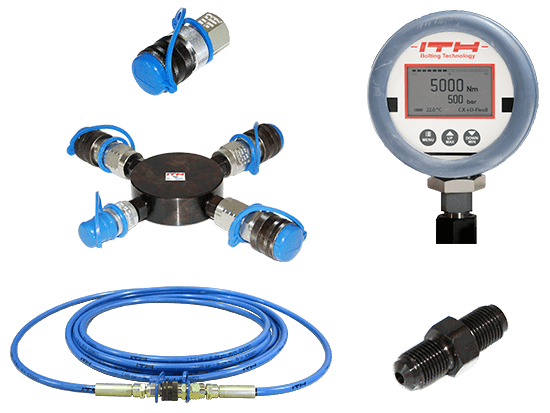

Multi-staged Bolt Tensioning Cylinder type MS: Corresponding equipment

-

Hydraulic equipment: high-pressure hoses | couplings | nipples | coupling distributors | test gauges.

-

Testing Bolt Tensioning Cylinders on-site: Automatic test procedure and digital documentation via industry-PC.

-

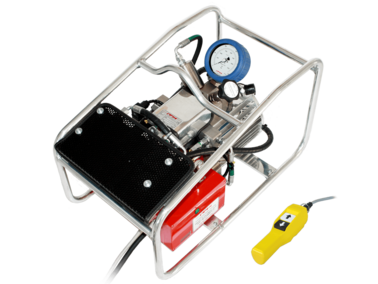

Electric, pneumatic, manual and battery-powered high pressure hydraulic pump series