Maintenance free bolted joints with IHF fasteners

HV-Stretchbolt and IHF Roundnut M 48 (1 3/4'').

IHF Stretchbolt and IHF Roundnut

- Stress-optimized design, no washers required

- Substitution of common bolts and nuts

Maintenance free bolted joint

- Proven by more than 3,000 measurements on wind turbines over 18 months

Approved by the German institute for technical approvals (DIBt)

Substituting common HV connections

Compared to conventional HV connection (one hexagon bolt, one hexagon nut, and two washers) the IHF Stretch-System reduces the connection to two core elements: IHF Stretchbolt und IHF Roundnut.

- IHF Stretchbolt: Stress-optimized bolt, the washer is integrated in the head of the bolt

- IHF Roundnut: Stress-optimized nut, large contact area

- IHF Stretch-System: IHF fasteners are applied with ITH bolt tensioning cylinders.

IHF fasteners are generally used in steel construction, especially on flanges.

Available standard dimensions are: M36 to M64 (1 3/8'' to 2 1/2'')

Repeatable pretensioning forces enable flange dimension reductions

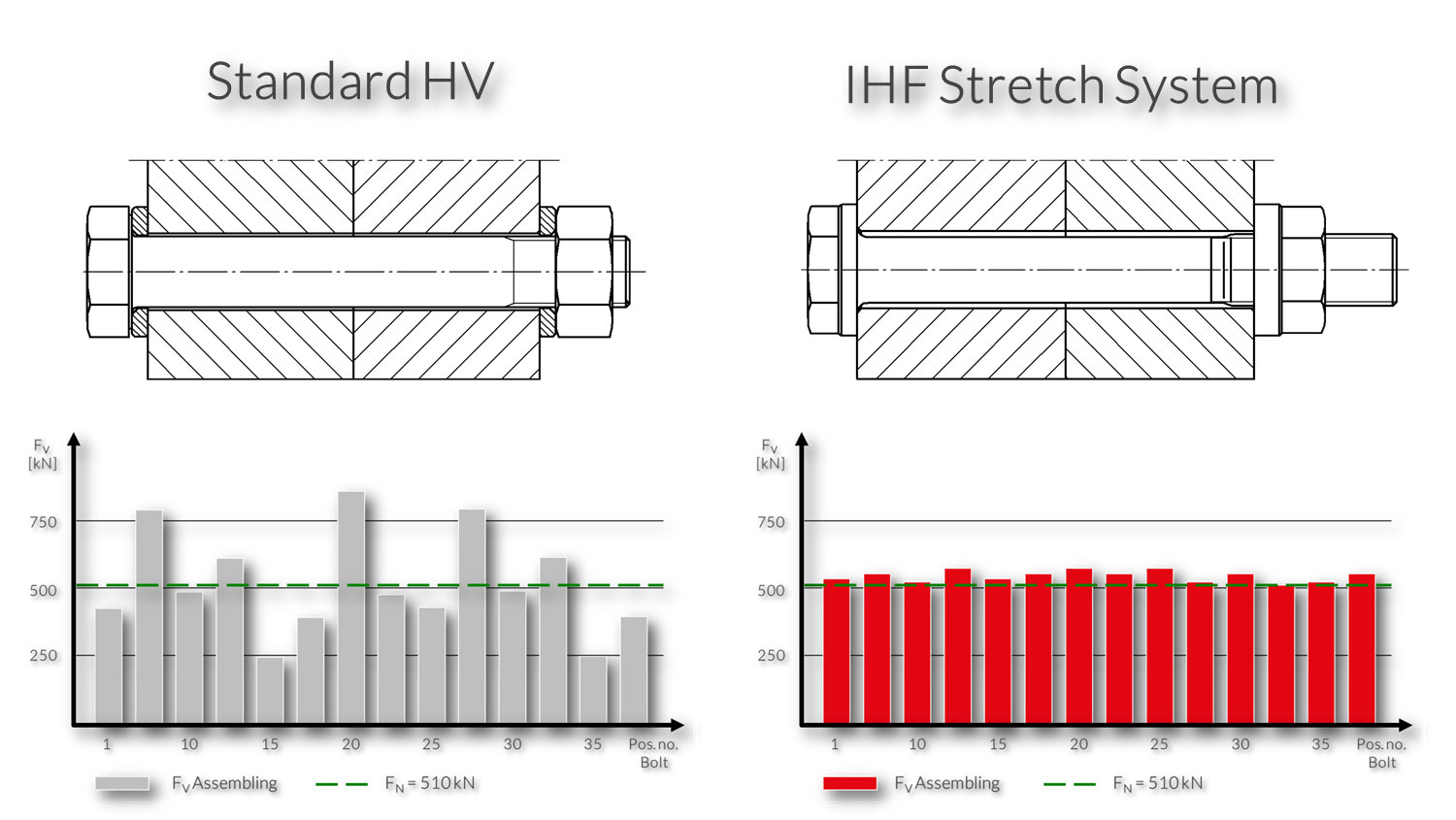

HV-connection with torque method

On conventional HV-connections the standard pre tensioning force is applied by torquing the nut with a hydraulic wrench. It is not uncommon to have very different friction coefficients from bolt to bolt with the torquing process. This in turn can lead to big fluctuations in pre tensioning forces. Therefore it is possible that the pre tensioning force on some of the connections is below the minimum pre tensioning force required. With dynamic loads a bigger stress intensity factor appears which can lead to bolt failures.

Innovative IHF Stretch-System

By using the IHF Stretch-System a higher repeatability of the pre tensioning force on the bolt is guaranteed. This improved connection allows

- longer maintenance intervals and therefore reduces maintenance costs. The more compact tensioning tool (bolt tensioning cylinder) makes it possible to reduce

- reduction of the distance from the center of the bolt to the casing inner wall. Thus the flange diameter of the ring can be reduced which leads to a considerable cost reduction

Technical advantages of the HV-Stretch-Systems

- No bending or torsional stresses in the bolt

- Higher utilization of the yield point

- Exact setting of the pre tensioning force

- System is working free of friction

- Repeat accuracy in working

- High repeatability of the pre tensioning force at several bolt connections

- Fast and safe assembly

- Smaller bolt dimensions with the same tensioning force

Cost advantages of the IHF-Stretch-System at a glance

- Less expensive flanges

Flanges can be designed more compact, the IHF fasteners allow a higher pre tensioning force with smaller flange diameters. The bolt spacing p at the flange is higher therefore the flange dimensions are reduced. - Less expensive tool costs

- Lower costs of the fastening elements

- Less Expensive maintenance - costs from higher repeatability during pre-tensioning

- Smaller bolt dimensions at same pre tensioning force

- Fast assembly

- Reduced crane and assembly costs

Bolting of a wind turbine tower section with an ITH BTC type MS, IHF stretch-bolt M56, and IHF Round nut M56. By reducing the outer diameter with the IHF round nut and chamfering the BTC support, the bolt connections can be put closer to each other which leads to reduced bolt spacing at the flange. Because of this a higher pre tensioning force can be used in a smaller flange dimension. The flange can be built more compact resulting in cost savings from less material.

IHF foundation bolts, IHF round nuts, and ITH equipment erecting of a wind turbine show before setting.

Fast run down of the IHF round nuts by a hand torque wrench with the direct gear drive at the ITH bolt tensioning cylinder type MS. The hydraulic pump ITH Hydro - MAX 18 (left) guarantees a fast pressure build up. The digital dial gauge measures the elongation of the bolt (ITH direct elongation measuring system).

The IHF fastener systems M36 of the blade bearing connection are tensioned evenly with 4 bolt tensioning cylinders at the same time (ITH-multi tensioning).

The bolted connection of a wind turbine tower segment with an ITH bolt tensioning cylinder type MS, IHF stretch-bolt M56, and IHF round nut M56.

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.