Hydraulic Bolt Tensioning Cylinder type ES, single-stage

Short and wide design

- Radially open but vertical limited clearance applications

Patented safety features

- The ITH safety concept consists of patented cycle counter, safety handle and safety fracture device

Standard and large-scale

- For bolted connections M16 (5/8") upwards

Tool-information: features, function, application examples and technical data

Triplex pump head application with four ITH BTC type ES 42

The simultaneous pre-tensioning of the bolts (using 4 tensioners at the same time, ITH Multi-Tensioning) allows a uniform and precise application of the pre-tensioning force. This improves the quality and the durability of a bolted connection. The possible risk of leakages is reduced significantly.

This ITH Bolt Tensioning Cylinder type ES 27 and the hydraulic pump ITH Micro-MAX 72 with the digital remote control are used on the foundation connection (M27, bolt quality 10.9) at a brewery exhaust air unit. After reaching the full hydraulic pressure the hex nut is tightened down via the direct gear drive with the help of a hand torque wrench. The hand torque wrench allows for controlled torque to be applied to each nut.

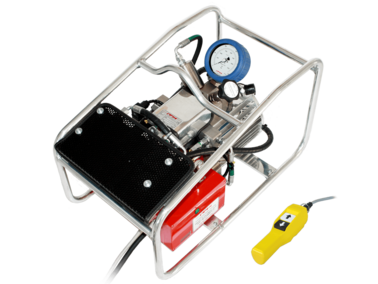

The compact pump series Micro-MAX are designed for service jobs.

Blade bearing connection of a wind turbine, tensioned with ITH BTC type ES 36 - 670 (M36 with 670 kN tensioning force). This BTC has a flexible carrying strap, a hydraulic block with cycle counter and a burnished surface coating.

Four Bolt Tensioning Cylinders type ES are pre-mounted to tighten the bolts of a flange cover simultaneously and precisely (ITH Multi-Tensioning). After the fast installation of the 4 tensioners they are all connected to a 4-way distribution block and connected to an ITH hydraulic pump. The ANSI flange cover is closed in a precise and uniform way, minimizing the risk of leakages.

Simultaneous and uniform tensioning of the 4 cylinder head bolts M30x2 (ITH Multi-tensioning) of the motor with Bolt Tensioning Cylinder type ES 30 -430 (Tensioning force 430 kN).

Optional Nickel-Chromium coating which prevents corrosion. The standard Bolt Tensioning Cylinders are protected by burnished coating.

The ITH safety concept for bolt tensioning cylinders include: patented cycle counter, patented safety handle, and patented safety fracture device.

- Counts each pressure cycle of the tool and clearly displays the current cycle

- Offers an easy way to track working procedures for users

- Improved tool management by tracking cycles for maintenance intervals and service, which promotes safe working conditions

Increases the operating speed of the tool. The integrated automatic piston return pushes the piston back to its original starting position when the hydraulic pressure is released (The change bushing position is even with the cylinder cover).

Accelerating the assembly: setting up the Bolt Tensioning Cylinder the inside turning sleeve automatically adjusts and contains the nut.

The control notch on the foot of the support offers an easy visual inspection to check, if the nut lays even with the surface before pressurizing the Bolt Tensioner.

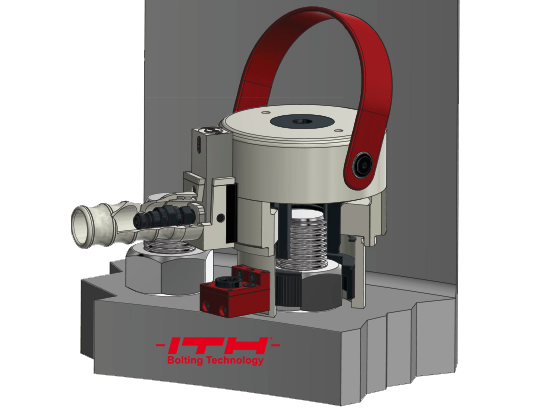

ITH Bolt Tensioning Cylinder type ES consists of a modular design:

- Adapt to different thread profiles with interchangeable parts. One Bolt Tensioner can fit different thread profiles by using the corresponding change bushing.

- Adapt to different nuts and washers with interchangeable parts. The support of the tool can be changed to accommodate all variations of nut and washer set-ups.

- Pin drive (left): Support with access window for tightening the nut using a turning pin. Can be used directly with slotted round-nuts or with a slotted Turning Sleeve fit for hexagon and other custom faced nuts.

- Gear drive (right): Standard Support with attached gear drive for tightening the nut using a hand ratchet. Can be used with all hexagon and other custom faced nuts. - Various hydraulic block options are available according to the application requirements.

Various hydraulic connection configurations can be choosen due to application requirements:

- Standard: horizontal with cycle counter

- Multi-tensioning hydraulic connection: male and female couplers on the hydraulic block, with or without cycle counter

- Without cycle counter: horizontal or vertical.

All horizontal connections are compatible with optional safety handle (on the left).

By a measurement slot - a hole throughout the change bushing - Bolt Tensioning Cylinders type ES are ready for optional digital documentation system (PSD / PD System). With an attachable digital measurement gauge the realized bolt elongation of each bolt can be measured. This allows to compare the realized force of each bolt connection among a series of bolting operations.

The carrying strap is durable yet flexible for better handling. For larger size tensioners ITH offers pneumatic spring balancers for easy lifting and handling. Furthermore the wholes on the sides can be equipped with ring loops for the transport by cranes.

The gear drive controls the nut rotation during the tensioning process and is compatible with standard hand ratchets (1/2” or 1/4”).

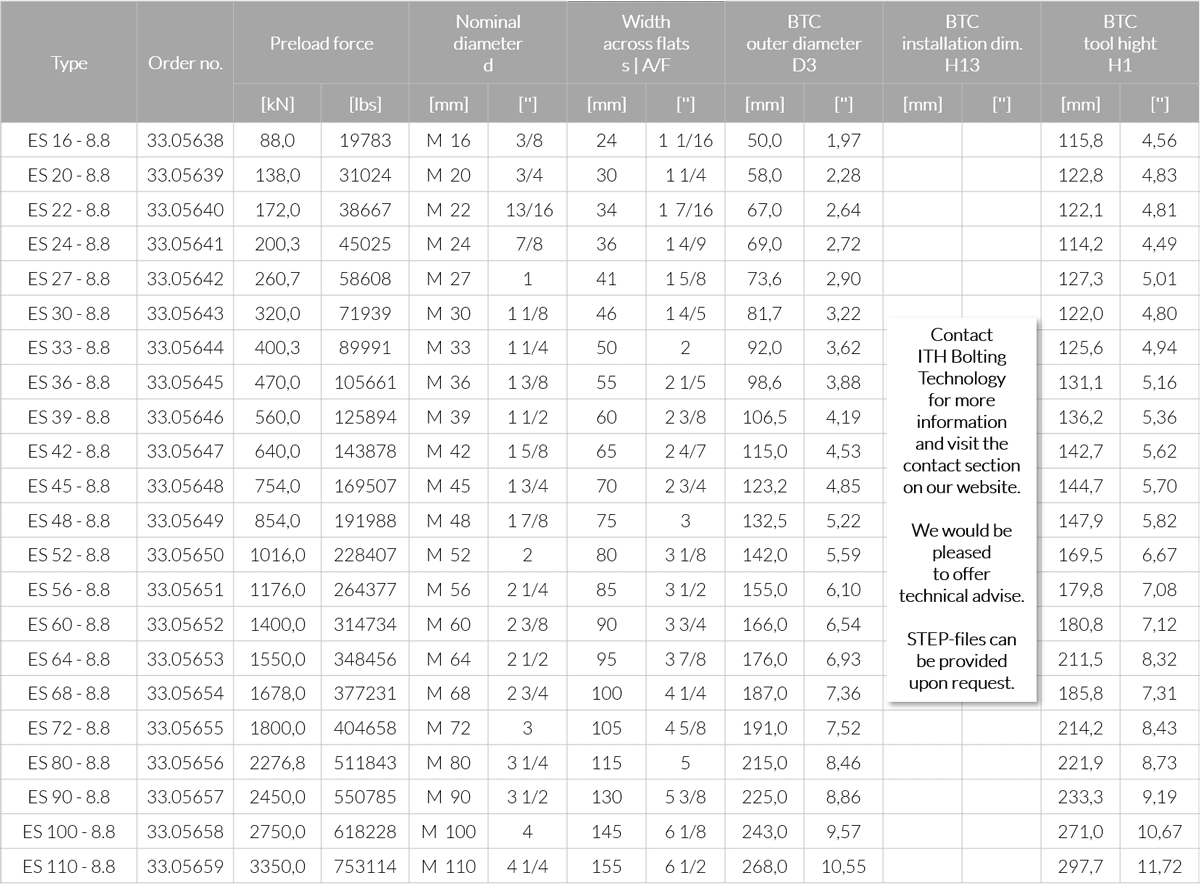

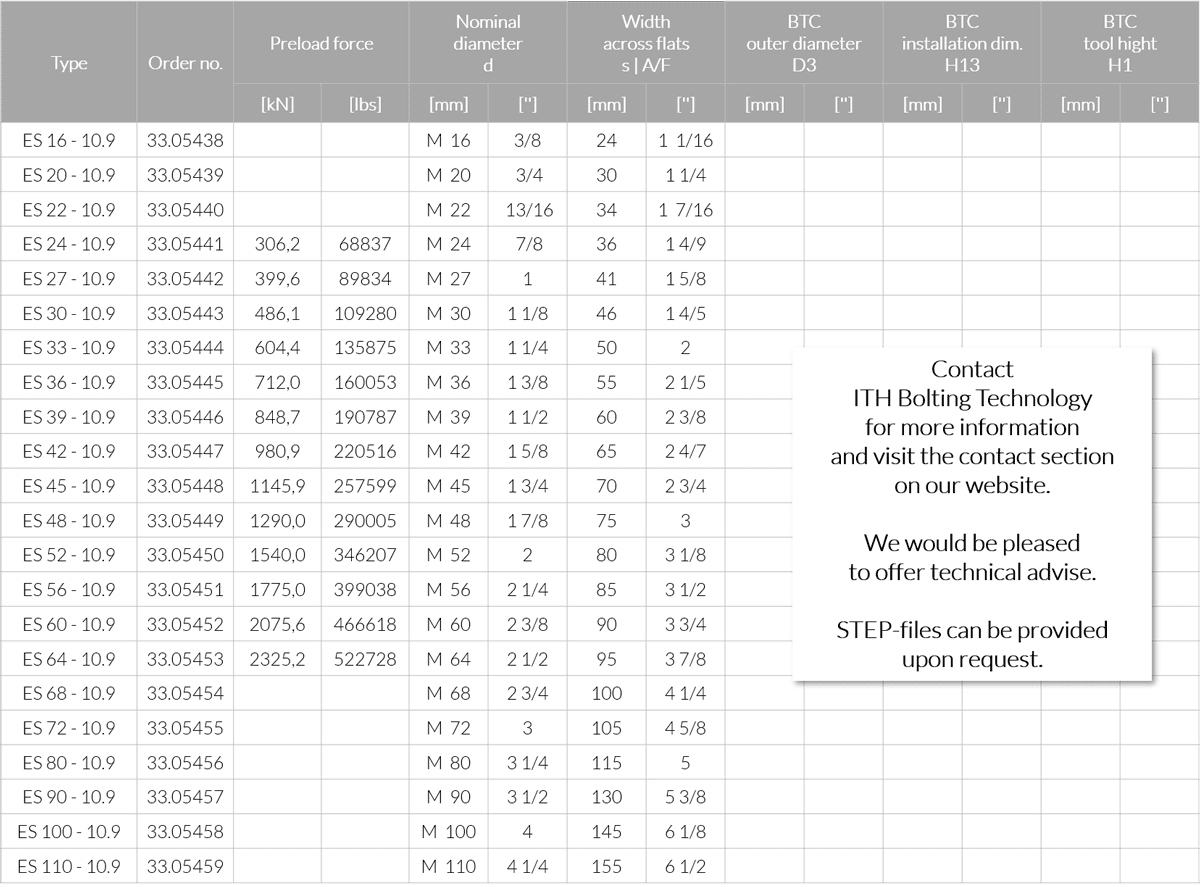

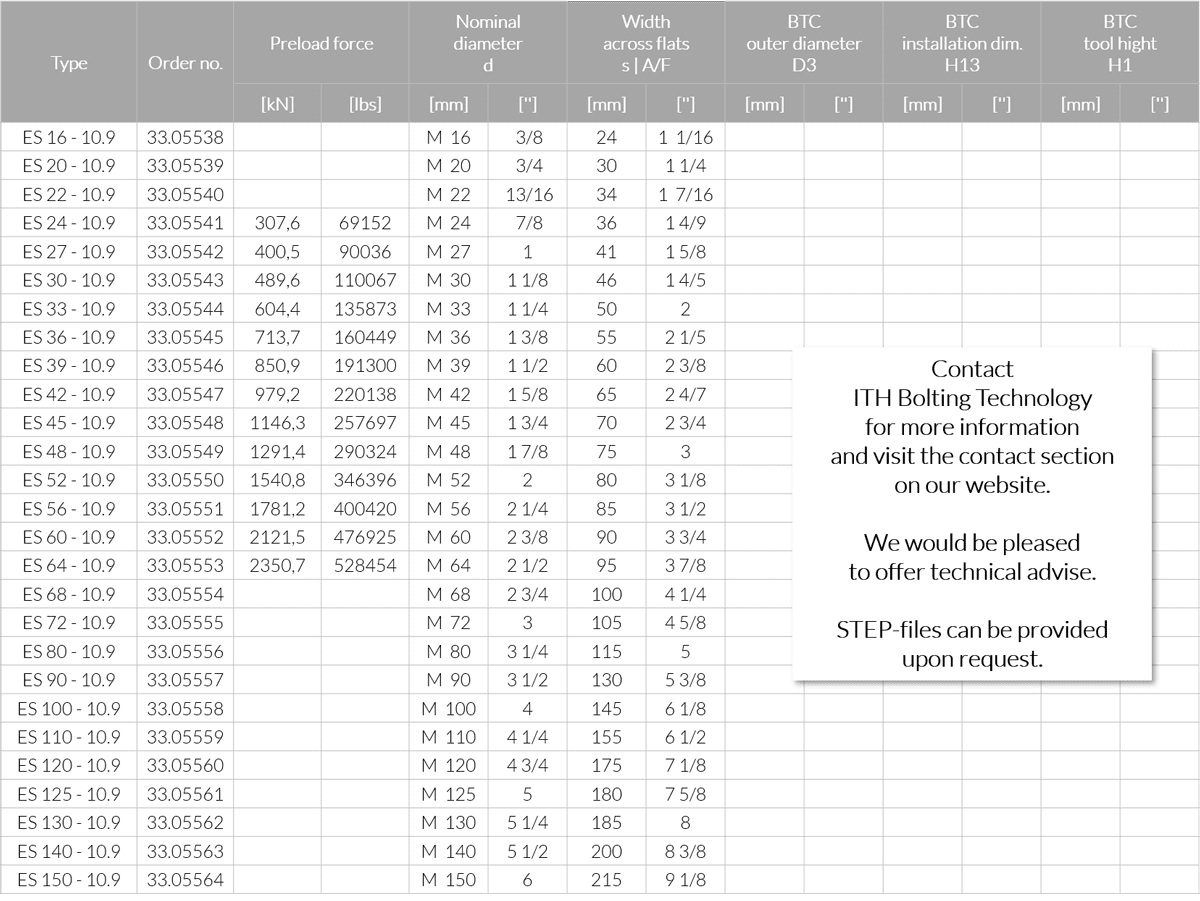

Type ES (single-stage): Short & wide design for radially open but limited vertical clearance applications

Standard scope

- design for bolt quality 10.9: M16 to M150

- design for bolt quality 8.8: M16 to M110

Special cylinders, customized designs for bolt qualities 5.6, 6.8 or 12.9 or further bolt qualities can be delivery on request.

Thread projection

The minimum of the thread projection of the bolt above the nut: 1,0 x d of the bolt (depending on the pre-load force; d = inner thread diameter).

Bolt Tensioning Cylinders can be used for the following fastener configurations:

Hexagon nuts

- ISO 4032: Hexagon nuts (former DIN 934)

- DIN 2510-5: Hexagon nuts

- EN 14399-4: High strength pre tension able bolt connections for the steel constructions (former DIN 6915)

- Heavy hex nuts

- Hexagon nuts according to customer designs

Round nuts:

- Round nuts with radial hole

- Round nut with center holes

- ITH Round nuts RMS /RMZ

- IHF Round nut

- Round nuts according to customer designs

ITH Bolt Tensioning Cylinder type ES for bolt qualities 8.8 and 10.9, from M16 (5/8") up to M110 (4 1/4")

Contact us for:

- bolt qualities 5.6, 6.8 und 12.9

- special customized designs

- further technical information

- a free of charge technical consultation

We would be happy to give advice on your individual bolted joint.

Large-scale Bolt Tensioning Cylinder ring, M36 x 4

Product description of the Bolt Tensioning Cylinder type ES

ITH Stretch-Method: The bolting process

- The bolt tensioning cylinder is threaded onto the bolt by use of a hand torque wrench or a battery nut runner.

- The calculated pressure is generated by an ITH high-pressure pump. This creates a torsion and friction free elongation of the bolt. The hydraulic pressure at the pump is directly proportional to the pre-load force of the bolt tensioning cylinder that is applied at the bolt.

- When the pressure has been achieved the nut is tightened down by use of a hand torque wrench for controlled torque output.

Advantages of the ITH Stretch Method in comparison to the conventional methods

In the conventional system (torque method) the pre-load force is applied by a mounting process which shows torsion and friction stresses at the nut and the bolt by torquing them together. During this process the torquing tool has to work against to moment of thread pitch and the friction at the thread on both laydown surfaces. At the assembling process the thread friction, the head friction- and moment of thread pitch come all together. The thread- and moment of thread pitch can have a value of 90% of the final torque value.

The assembly pre load shows a high deviation based on the deviation of the friction values of the thread and under the head of the volt. The friction value by friction class B shows a deviation from 0.08 to 0.16, by these values the pre-load force can deviate by about 100%.

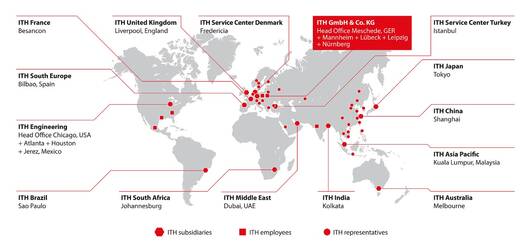

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

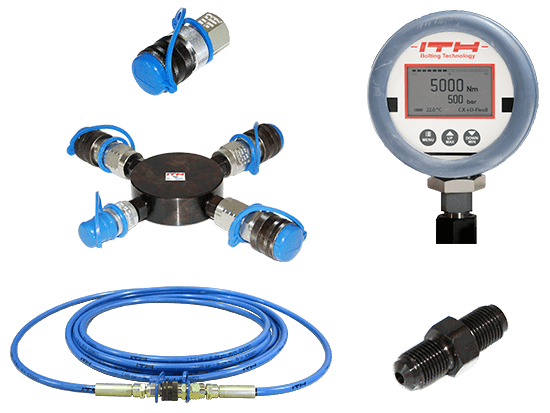

Bolt Tensioning Cylinder type ES: related equipment

-

Hydraulic equipment: high-pressure hoses | couplings | nipples | coupling distributors | test gauges.

-

Testing Bolt Tensioning Cylinders on-site: Automatic test procedure and digital documentation via industry-PC.

-

Electric, pneumatic, manual and battery-powered high pressure hydraulic pump series