Low profile hydraulic torque wrench cassette-type D-Flex

Key features at a glance

- Flexible cassette-type hydraulic torque wrench: One cylinder unit of the hydraulic torque wrench can run up to 8 cassettes with different A/F.

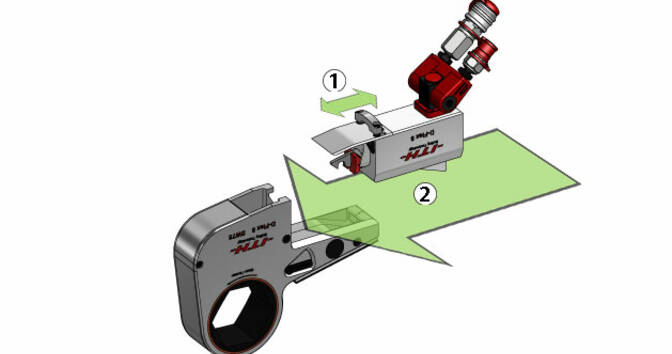

- Quick change mechanism "QUICK-AND-GO" between cylinder and cassette allows for a quick and easy interchange by hand. There are no extra tools required for the interchange!

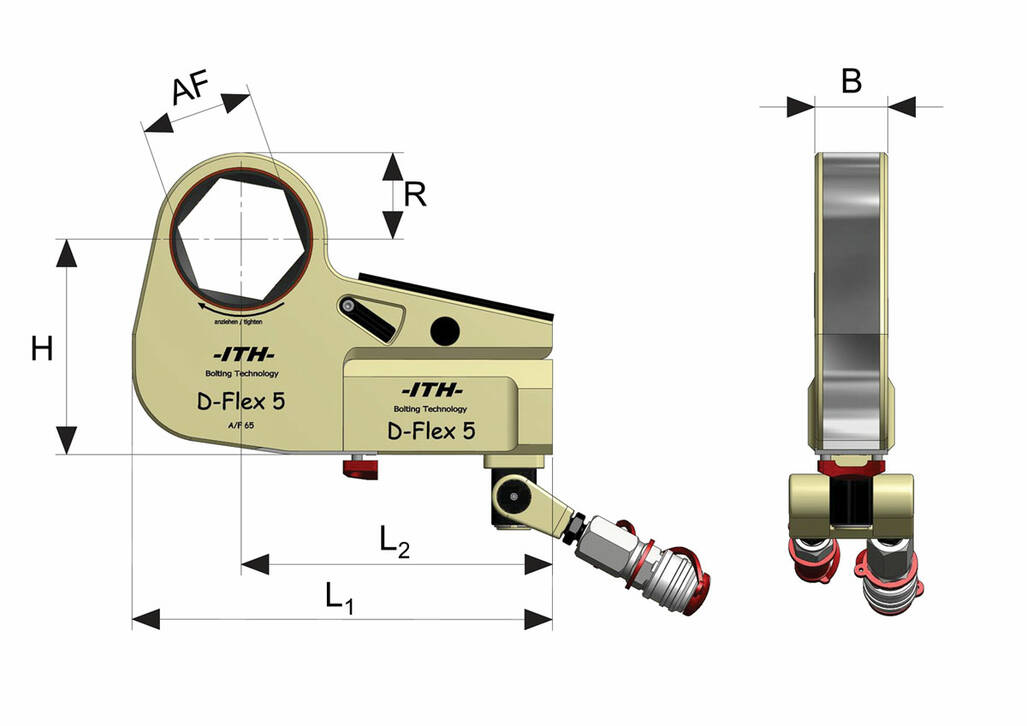

- Compact and light-weight tool dimensions are guaranteed by reduced head radiuses and an extra low-profile design. This allows for easy handling on sites.

Reduced D-Flex head radiuses are beneficial for all bolting applications. Furthermore the hydraulic torque wrench type D-Flex is designed to match pipe flange standards:

- ASME B16.5 (Pipe flanges, class 300 to class 2,500)

- MSS SP-44 (Steel pipe flanges, class 150 to 900).

Application examples of the hydraulic torque wrench type D-Flex

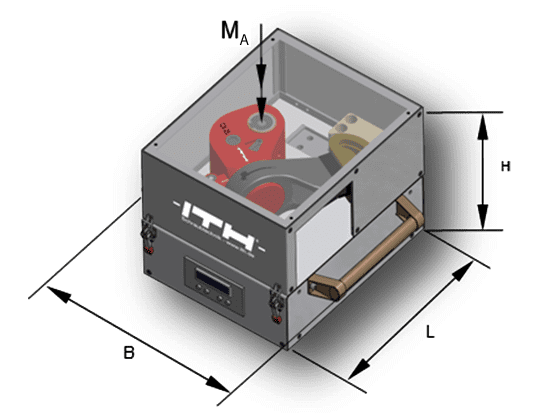

Low-profile hydraulic torque wrenches type D-Flex can optionally be added with the ITH System ALPHA, which is a system for angle-controlled bolt tightening. Therefore and ALPHA sensor unit (red casing in the picture) can be mounted on to the D-Flex easily. The sensor unit is corresponds with the ALPHA control box at the ITH hydraulic pump unit, connected by a data wire.

Contact your local ITH representative for more information about the angle-controlled bolt tightening method. We would be happy to provide support.

Reduced head radiuses of the cassette units of the hydraulic torque wrench are beneficial on all applications where space is limited.

Furthermore ITH hydraulic torque wrench type D-Flex design matches the following flange standards:

1. ASME B16.5 (Pipe flanges, class 300 to class 2,500)

2. MSS SP-44 (Steel pipe flanges, class 150 to 900)

In the picture above D-Flex 5 is applied on a steel flange model according to MSS SP-44 class 600 (ratio 1:1).

On-site ready, robust and flexible: ITH hydraulic torque wrench type D-Flex 5 tightens bolts of a steel construction of a ropeway, powered by an ITH pump unit Hydro-DAX 18. The remote allows for easy one-man operation. The dual-hose system offers high-speed bolting procedures.

Pictured above is a main bearing to generator bolt connection of a wind turbine. In this case there is only a small distance from bolt center to bolt center (bolt spacing t), plus there is only a small distance from bolt center to the component wall.

Because of reduced head radiuses hydraulic torque wrench type D-Flex matches these kind of technical challenges. By an "in-line" or direct support the hydraulic torque wrench reacts directly at the next bolt. This avoids bending effects inside of the torque tool.

Features of the flexible cassette-type hydraulic torque wrench D-Flex

Direct "in-line" support design avoids extra bending effects inside of the hydraulic torque wrench which is beneficial towards the positioning of the torque tool.

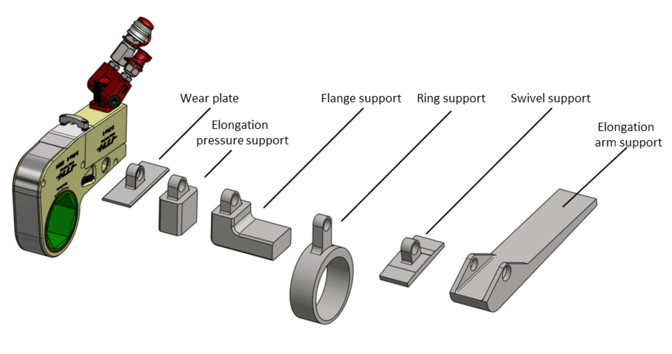

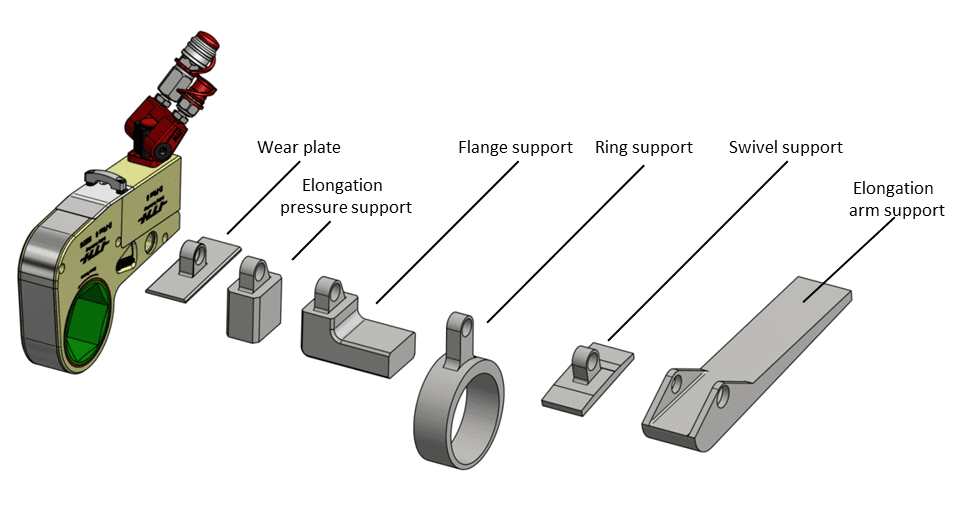

Standardwise the D-Flex comes with a hardened support plate ("wear plate"). All support options which are shown above can be interchanged quickly and easily.

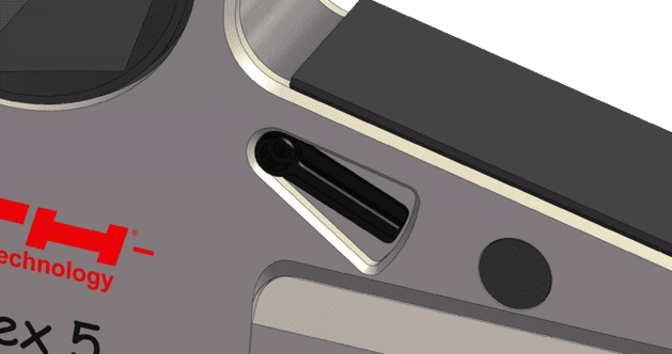

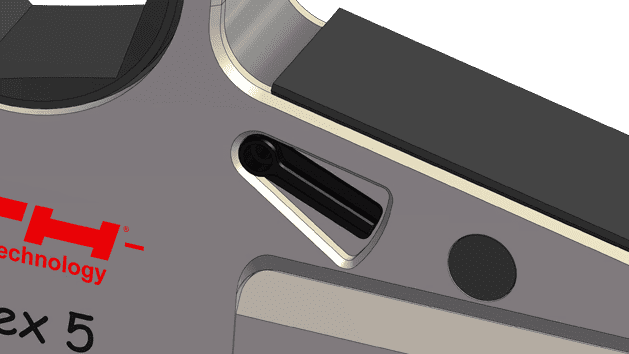

ITH "TORQUE-FIX" mechanism holds the hydraulic torque wrench in position, hands-free, especially useful on overhead applications.

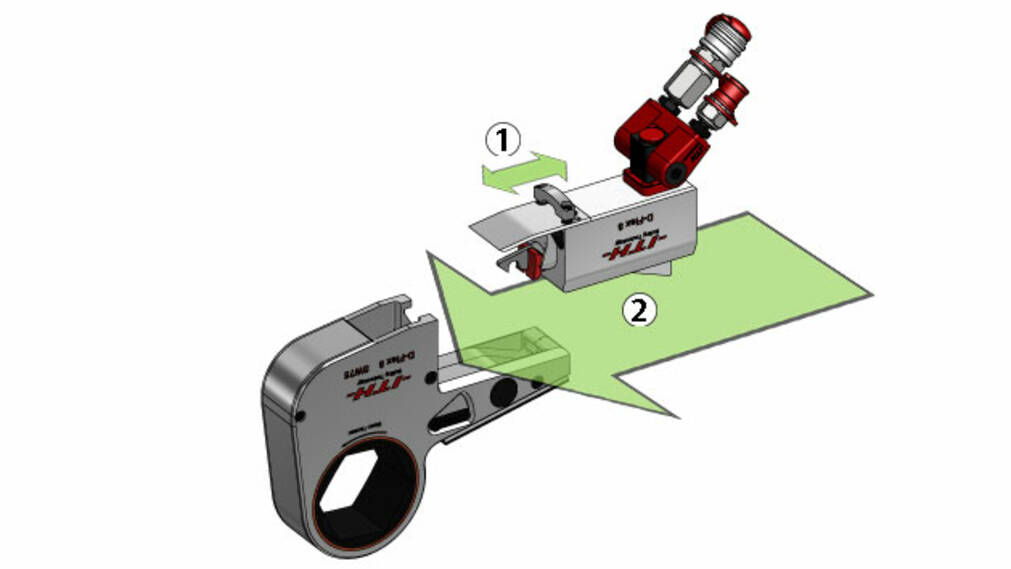

Easy and fast changing of the cassette units is provided by the quick change mechanism "CLICK AND GO". There are no extra tools required to change the cassettes!

- To remove the cylinder from the cassette just pull back the robust handle to unlock.

- To connect cylinder and cassette just click-in both parts.

- No extra tools required.

Expand your application options for low-profile hydraulic torque wrench type D-Flex with several, available sockets. Find the range of hydraulic torque wrench sockets here.

One big benefit of the cassette-type hydraulic torque wrench is their modular and flexible design. One cylinder unit and run up to 8 different cassette units with different A/F.

This guarantees we can provide an optimal designed tool for your application.

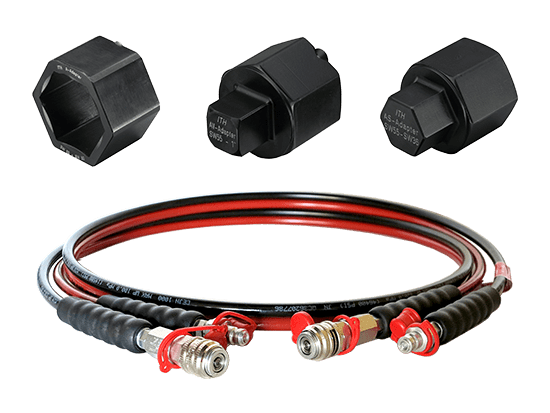

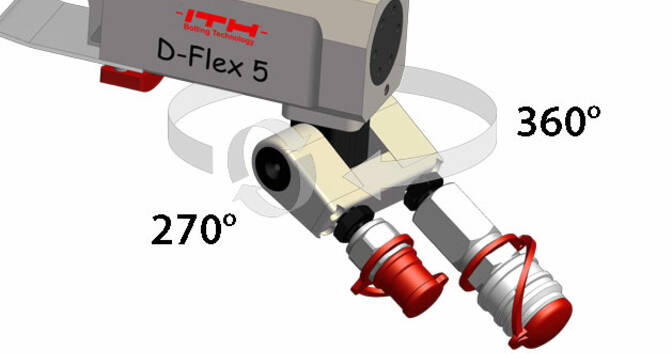

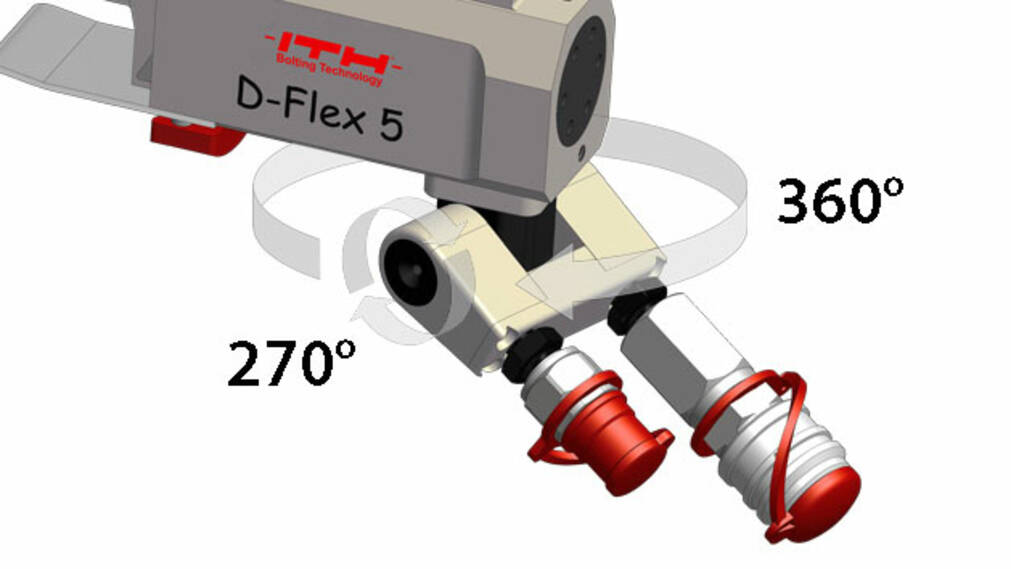

The dual-hose hydraulic connector with 2 swivel points offers maximum flexibility when positioning the tool and hoses. The ITH dual-hose system including "high flow" nipples guarentees fastest bolting procedures.

Find more information about our dual-hose pump units for hydraulic torque wrenches here.

The reduced head radiuses of the cassette units allow the hydraulic torque wrench type D-Flex fit into smallest bolt spacings between 2 bolts.

This is beneficial on all applications. Furthermore the D-Flex matches the following flange standards:

- ASME B16.5 (pipe flanges, class 300 to 2,500)

- MSS SP-44 (steel pipe flanges, class 150 to 900)

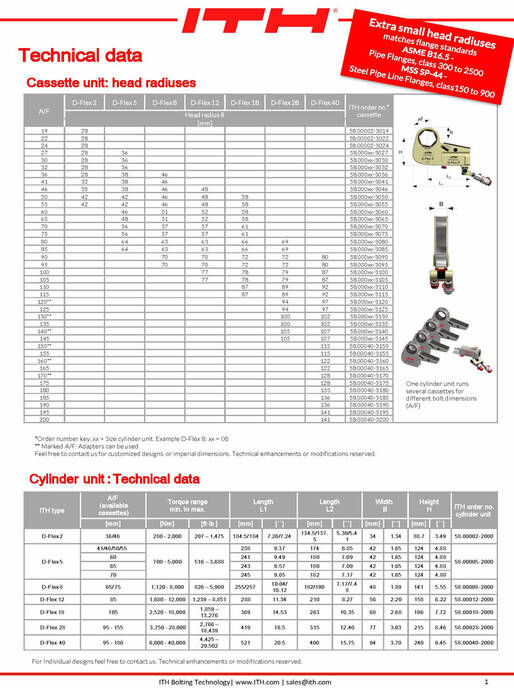

Technical data of the hydraulic torque wrench type D-Flex

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

Related hydraulic equipment for low-profile hydraulic torque wrench type D-Flex

-

Testing Hydraulic Torque Wrenches on site with the mobile test stand.

-

High pressure dual-hoseline, various sockets and insters for hydraulic torque wrenches.

-

Overview all ITH hydraulic pump series for hydraulic torque wrenches: electric | pneumatic | manual types for single- and dual-hose systems.