Products

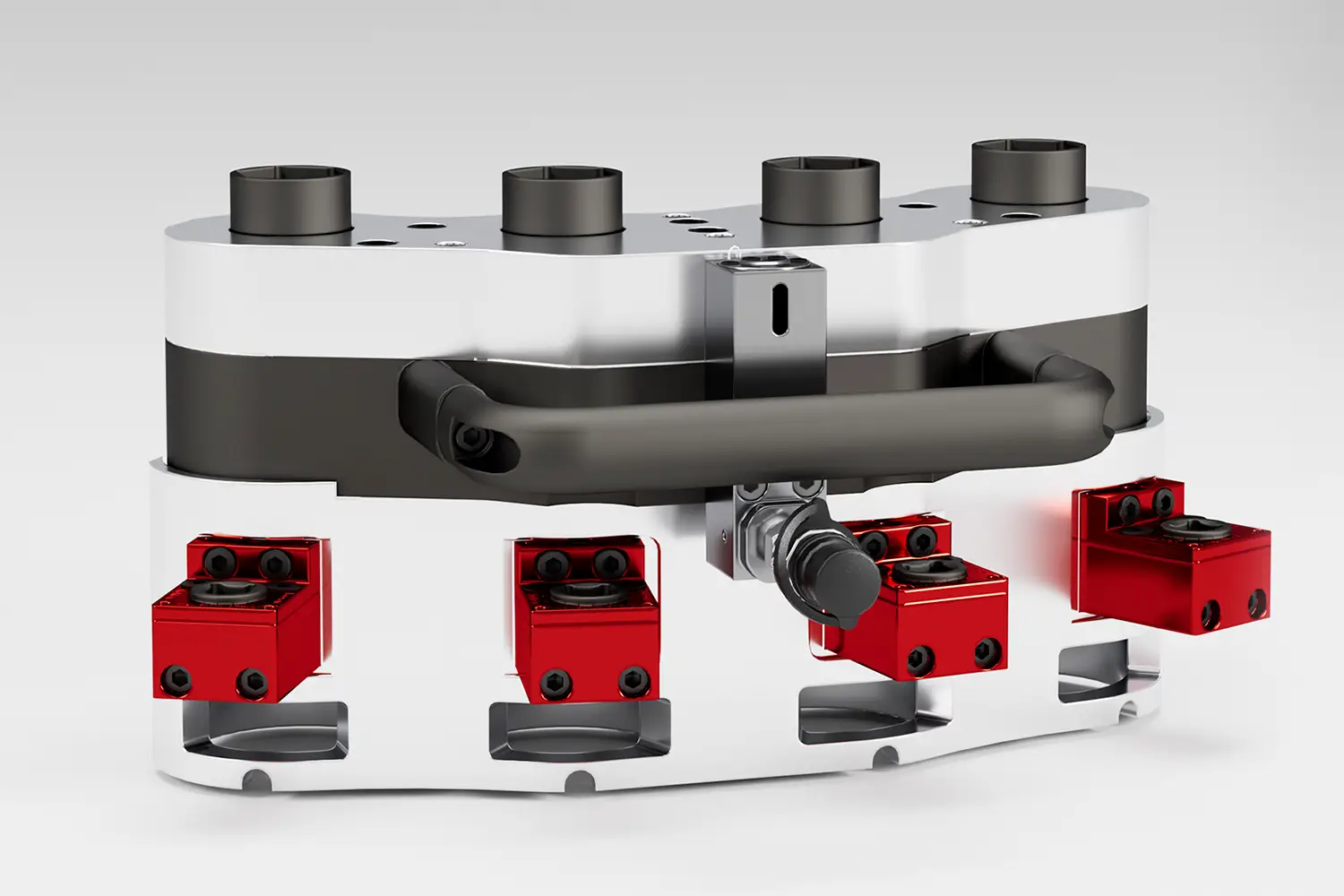

Bolt Tensioning Cylinder

Products

All Bolt Tensioning Cylinders

Compact

Ideal for axially limited applications

Safe

thanks to break load protection & cycle counter

Slim design

for radially confined applications

Patented safety

through innovative security architecture

Designing

Designed for bolt quality 8.8

Versatile and usable

As standard for M16 to M110

Open design

Hollow piston cylinder, for long thread projections

Flexible lock nut

Enables quick pushing

Efficient flange mounting

for minimum downtimes

Compatible & Versatile

For all common flange standards

Simultaneous pre-tensioning

Uniform preload for all bolts

Process reliability

Effectively reduces the risk of leaks in flange connections

Powerful

High preloads

Precise

Axial pre-tensioning

Accessories

Accessories for Bolt Tensioning Cylinders

Safe

Drip-free coupling

Durable

Galvanized steel construction

Strong and resistant

High abrasion resistance

Flexible

Small bending radius

Precise

Accuracy classes up to 0.25

Strong and resistant

Impact-resistant pressure gauge housing

Flexible

with multiple distributor

Safe

up to 3,000 bar

ITH Smart Tools

With ITH Smart Tools, you can make a wide variety of bolting tools simple and smart – regardless of the device type. Thanks to the cloud connection, you can detect, monitor and document assembly processes centrally, across locations and in real time. Benefit from maximum transparency, efficiency and traceability in your production.

PROJECTS

Our products in use

Contact us