Extending the required projecting thread for to use the hydraulic, torsion- and friction-free tensioning. Existing bolts can remain.

Tension Nut type TN

Tightening bolted connections with ITH Tension Nuts

- Easy substitution of existing standard nuts

Achieving the required projecting thread

- Using the hydraulic tensioning method (using ITH Bolt Tensioning Cylinders), a certain projecting thread above the nut is required

- If this projecting thread is not available the ITH Tension Nuts extends the thread to its required length. Existing bolts do not have to be replaced. When retrofitting bolt connections to hydraulic tensioning

Design

- Three main components, based on the differential thread principle

Applications

- High temperature areas

- Foundation bolts (anchor rods)

can easily be retrofitted to hydraulic tensioning

Function, application and technical data of the ITH Tension Nut

Retrofitting foundation bolts with ITH Tension Nuts

On this application conventional nuts of anchor rods of a wind turbine are replaced with ITH Tension Nuts TN 36 (retrofitting). It has become standard to tighten foundation bolts with the hydraulic, friction- and torsion-free tensioning method (ITH Stretch-Method).

The reason for this is that especially foundation bolts are negatively affected from bending and torsion effects which occur when tightening bolts by torquing. In worst case these effects can lead to a collapse of the bolt connection.

A safe and reliable solution to tighten and loosen anchor bolts is to use ITH Bolt Tensioning Cylinders. Together with the use of ITH Tension Nuts, existing bolts can be kept and do not have to be replaced when retrofitting bolt connections.

By its compact and stress-optimized design Tension Nuts can be used in tight application areas, like this Tension Nut TN 140 on the bolted connection of a rolling machine. This Tension Nut was tightened with 3,500 kN.

These Tension Nuts type TN 72 are equipped with radial boreholes inside of the pressure sleve to run them down. The Tension Nuts have been tensioned with 1,900 Nm.

ITH Tension Nuts are ready for the use in high-temperature areas like on the bolt connections of this gasturbine (operating temperature ca. 550°C). On this application the pressure sleve of the Tension Nut can be run down easily with an adjusting stick. The stick reaches the pressure sleve through a window within the support of the Bolt Tensioning Cylinder.

The ITH Tension Nut consists of 3 main components:

- Tensioning sleeve

- Pressure sleeve

can be hexagon, two-flat design or with radial bored holes - Pressure disk

Function and design

The method by which the three-part patented ITH Tension Nut works is based on the principle of a differential thread. A special threaded sleeve (tensioning sleeve) which is bolted onto the bolt transmits the axial pre-tensioning force from the bolt via the sleeve to the pressure disk and then to the flange.

This causes axial stretching of the boltwhich means that no additional torsion or other stresses can occur in the bolt. This causes purely axial stretching of the bolt. The pressure sleeve is then turned into position by a gear wheel block on the Bolt Tensioning Cylinder or by an adjusting stick.

During the process no bending or torsion effects are applied on the bolt.

Usage togehter with ITH Bolt Tensioning Cylinders

Bolts which are pre-tensioned by the hydraulic, friction- and torsion-free ITH Stretch-Method require a thread projection of 0.8 to 1.0 x thread diameter above the nut. In case this projecting thread does not exist the bolts in place would have to be replaced by longer ones.

The ITH Tension Nuts have the effect to extend the projecting thread to its required lentgh. Existing nuts can easily be replaced by the Tension Nuts. The existing bolts do not have to be replaced.

Advantages of the application in high-temperature areas

With the ITH Tension Nuts the bolt is stretched only in an axial direction. This means that the ITH Tension Nuts are ideal for joints which are subjected to high temperatures because (in contrast to the torque process) the static friction does not have to be overcome when bolts are loosened.

When the torque process is used with bolt joints which are subject to thermal stresses, a torque has to be applied which is between 2.5 and 4 times greater, depending on the temperature in question to open the bolt. This can lead to serious damages to the hardware that they have to be replaced, thereby creating additional costs. In addition, the torque tool is often damaged by the sudden release of energy

during loosening (additional cost).

The patented ITH Tension Nut produces better distribution of stresses inside of the bolt. In contrast to conventional nuts, the use of the patented ITH Tension Nut considerably improves the fatigue strength of the bolt.

Through the special thread of the tensioning sleeve and the geometric arrangement, a very even distribution of stresses is achieved in the components of the patented ITH Tension Nuts. All patented ITH Tension Nuts have been designed due to the analysis with the finite element method (FEM).

Contact us for a technical consultation free of charge, for technical questions or individual designs of ITH Tension Nuts.

Tension Nut type TN

Technical enhancements or modifications reserved.

Contact your local person in charge

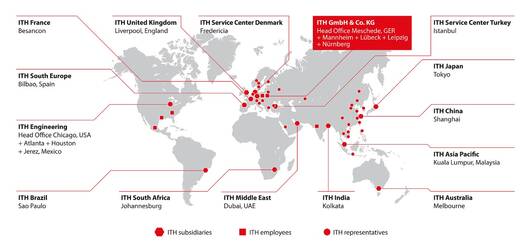

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

ITH Tension Nut: Relating products and solutions

-

The competence center of bolting technology: Development of industry-specific or customer-specific bolting solutions, engineering services and dvelopment of new standards by innovation and quality.

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.