Digital documentation and management for applications with ITH Bolt Tensioning Cylinders

Hydraulic bolt tensioning cylinder documentation system PD / PSD

Pressure documentation and pressure-stretch documentation

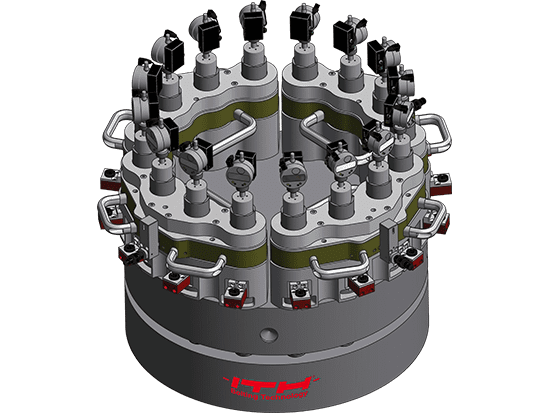

ITH documentation systems for all ITH bolt tensioning cylinder types. (pictured: Version PSD system, applied to ITH segment cylinder ring)

Automatic control

- of the bolting processes with ITH bolt tensioning cylinders

- Automatic pressure build-up (APC-Control)

Application management

- Easy application and control of all relevant application data

ITH Software

- User friendly, clearly, customized programmable

Measure the elongation of each bolt

- Option PSD: Digital measurement of the achieved pre-load forces during the bolting process.

Easy documentation

- Save the measured results easily with automatically generated Excell- or PDF-files

- USB-ports or wirless LAN transfer

Function of the digital management system PD / PSD

The digital documentation system has a modular design

Fundamental functions

- Automatic control of the hydraulic pump

The digital documentation system applies the pressure automatically. After reaching full-pressure the pump is managed to maintain a constant pressure level (ITH APC Control). - Clear and simple management of all relevant application data

All relevant application data is managed with customizable ITH software via touchscreen PC or tablet. All data is documented and controlled within the complete system.

Versions of the ITH documentation system

- Pressure Documentation System (PD-System)

The PD-System measures and documents the hydraulic pressure that is applied to the bolt connection. The data can be transferred over USB connection and then processed further or output. - Pressure Stretch Documentation (PSD-System)

The PSD-System measures and documents the hydraulic pressure and the elongation of every bolt . For this level of documentation digital gauges are installed on the bolt tensioning cylinders. These gauges transmit the measured data wireless to the PSD-System by bidirectional transmission.

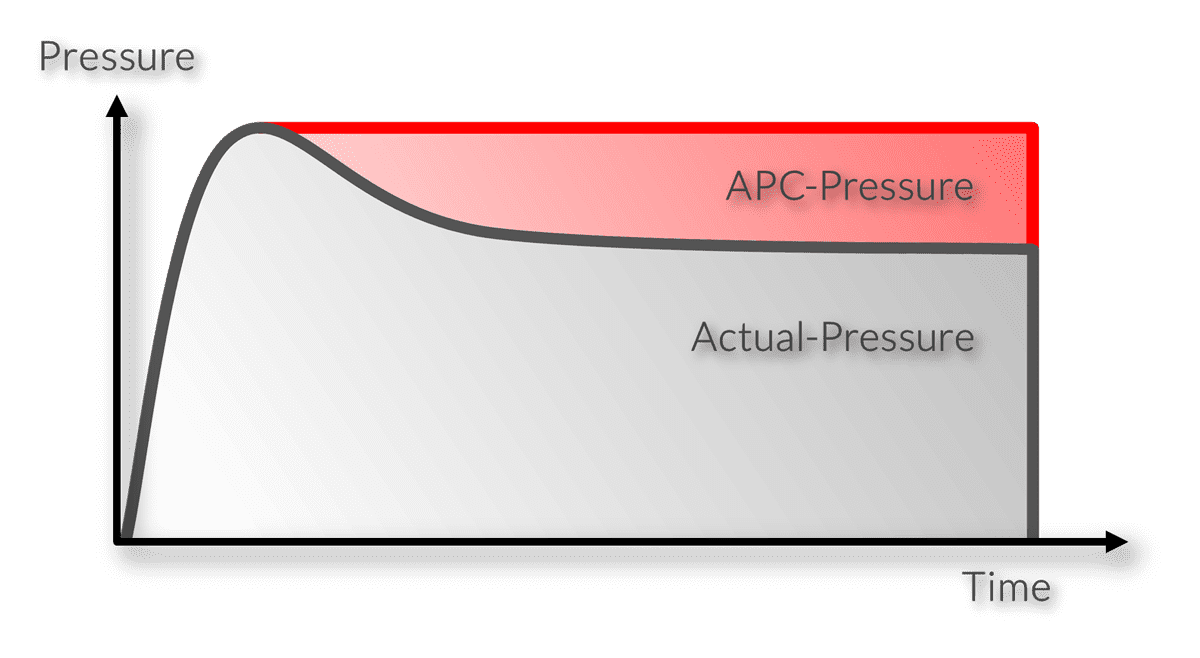

Pressure monitoring with the Automatic Pressure Control APC

During Bolt Tensioning Cylinder operation the pressure can drop due to expansion of the hose lines or compression of the bolted joint. This pressure drop can affect the final preload in the bolt. The digital automatic pressure control APC readjusts the pre-set pressure continuously and ensures a high degree of accuracy in the bolt's preload.

Function

The digital pressure monitoring Automatic Pressure Control (APC) allows:

- Constant monitoring of the hydraulic pressure, automatic readjustment of the hydraulic pump

- Entering the needed pressure via keypad

- Suitable for on-site use with large buttons, emergency stop switch, and robust housing

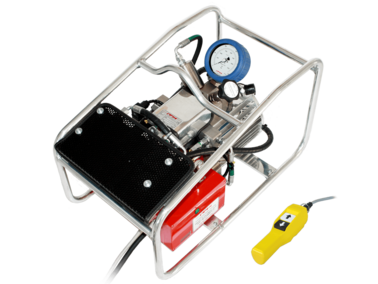

The multi-function remote of the APC uses a remote connection cable and can optionally be mounted directly in the frame of the pump. The automatic pressure control can be used with following ITH hydraulic pumps and systems:

- ITH Hydro-MAX 18, 38, 39,

- ITH Eco-MAX 18

- as a component of the ITH digital documentation system PD / PSD

The robust multi-function remote can be

- mounted to the pump frame (like in the picture)

or alternatively - produced as a flexible hand-held remote.

- Customer specific application data and hydraulic operating pressures can be recorded within the ITH software.

- The user enters all relevant application data starts the mounting process.

- The bolting process can be easily tracked (Process status - display) and controlled.

- The values of the applied pressures (PD - System) and the applied bolt stretch (PSD - System) are documented and can be imported to Excel or PDF files for any further processing.

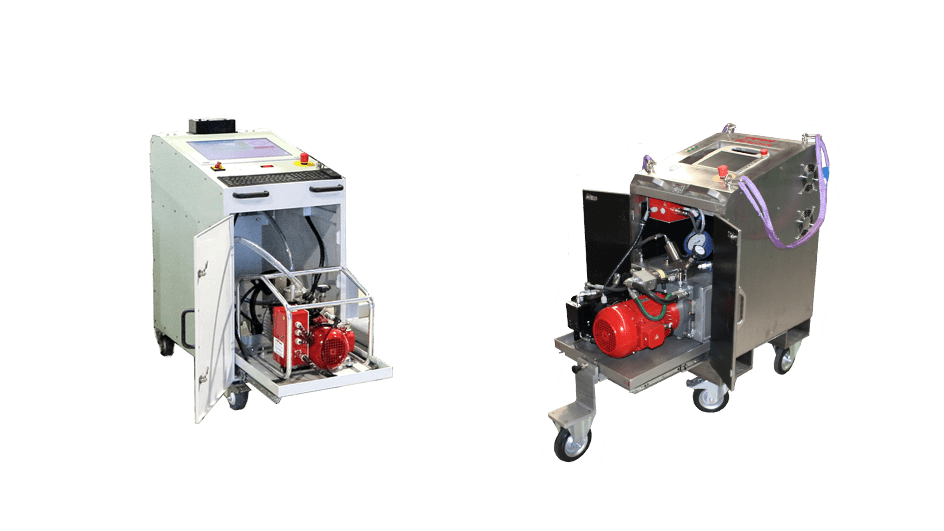

Three main components

- ITH Bolt Tensioning Cylinders

One or more Bolt Tensioners, all types - ITH high-pressure hydraulic pump

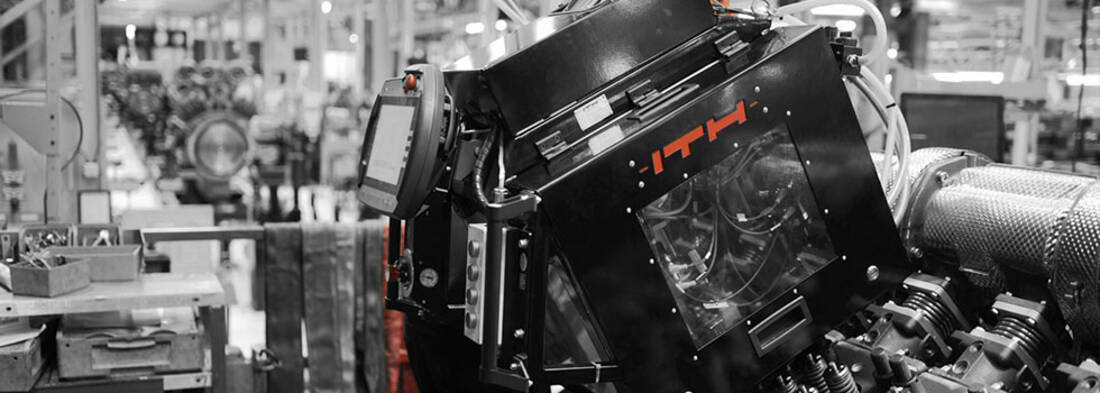

Integrated in a system wagon. Available for electric and pneumatic high-pressure hydraulic pumps - ITH documentation system

ITH measurement and control software, installed on an industrial PC at the system wagon. Also available on tablet PC and digital gauges

Measuring the applied pre-load force and digital application management

For use with the ITH Bolt Tensioning Cylinders the ITH documentation system enables:

- Easy and digital application management

- Automatic control and analysis of the bolting process

- Measurement of the applied hydraulic pressure

- Option: Measurement of the applied bolt stretching (the applied pre-load force)

Fundamental features of the system wagon

- Integrated touchscreen PC

- One USB port

- Mobile transport: 4 castors (2 swivel), 2 fork lift shoes, 2 robust handles

- Integrated drawer with oil reservoir for the ITH hydraulic pump (electric or pneumatic hydraulic pump availbable)

- Emergency stop switch

- Cable carrier on back

- 2 hydraulic couplings

Options:

- Mobile industry tablet PC (pictured on the right)

- System wagon made out of stainless steel (pictured on the right) with integrated fans

- Eyebolt lifting points

- Barcode scanner

- Additional USB interfaces

- Additional hydraulic couplings

- Digital gauges, optional with wireless data transfer

Contact your local person in charge

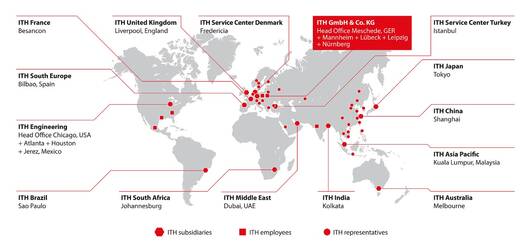

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

ITH documentation system PD / PSD: related tensioners and equipment

-

Electric, pneumatic, manual and battery-powered high pressure hydraulic pump series

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Tensioning flange bolts in one operation with multiple tensioners combined into single unit design.