Torquemeter for ITH Nut Runners

Measuring and testing

- of the applied torque values and torque angles during the bolting process

- for torque ranges from 125Nm up to 6.000Nm

Digital-Display

- Clear display of the torque values

Mobile usage

- Ready for on site use including integrated battery

- Available with 110V or 230V

Certified precision

- Accredited by the strict regulations of the German Accreditation Body DAkkS (former DKD)

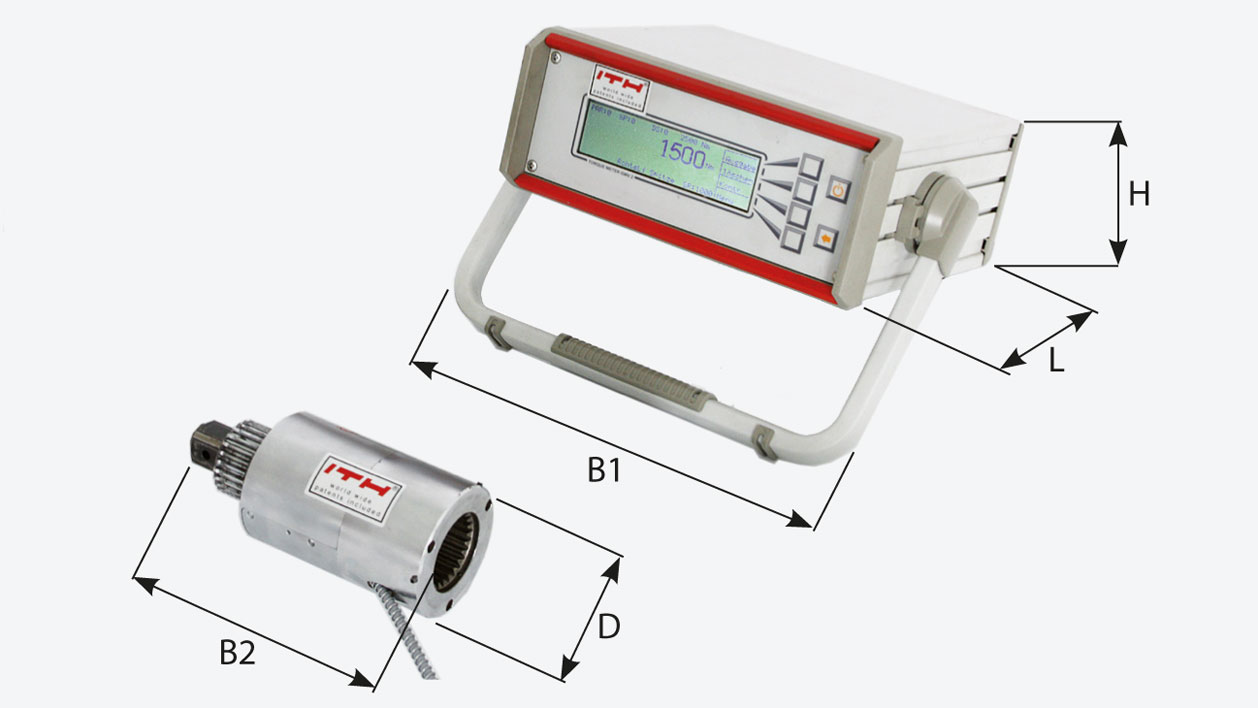

Features, applications and technical data of the Torquemeter

Torquing system

During the torquing process the preload force can vary from bolt to bold. This depends on several factors like the friction between the thread of the bolt and nut, the friction between the surface and the nut, the torsion load of the bolt and material specific factors.

Controlling the pre-load forces

The applied pre-load forces can be measured and controlled by the ITH Torque Tester. Therefore a sensor can be adapted easily between the ITH Nut Runner and the torqued nut. The fine toothed housing provides an easy connection. The socket will be secured on the sensor with a safety pin.

Measuring the applied pre-load forces and torque value using the Torquemeter together with this ITH Nut Runner EDS α 75 on the bolt connetions of this generator foot. The sensor of the Torquemeter can easily be positioned in between of the Nur Runner gear box and the socket. The digital display gives a direct feedback about the applied forces.

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

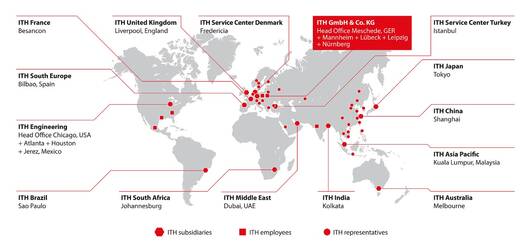

ITH Torquemeter: Relating accessories and torque tools

-

Side-drives, extensions, various inserts, and special reaction arms

-

Electric, pneumatic and battery powered torque wrenches which operate due to the torque method respectively to the torque-angle method.