Testing Bolt Tensioning Cylinders on-site automatically including ITH application software and measurement of the pre-loads

Hydraulic bolt tensioning cylinder calibration and testing with the ITH BTC Test stand

Automatic testing process on-site

- for ITH Bolt Tensioning Cylinders M20 to M72 (3/4" to 3")

Digital documentation

- Easy output of test data with automatically generated Excell or PDF-files

Easy and user friendly

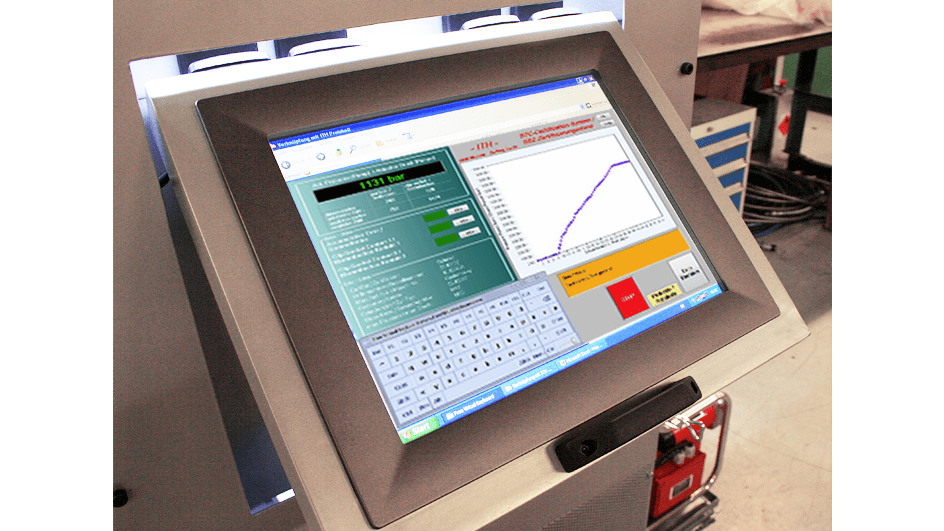

- ITH management software with touchscreen display

Certified precision by DAkkS

- Accredited by the strict regulations of the German Accreditation Body DAkkS (former DKD)

Description of the testing procedure and features

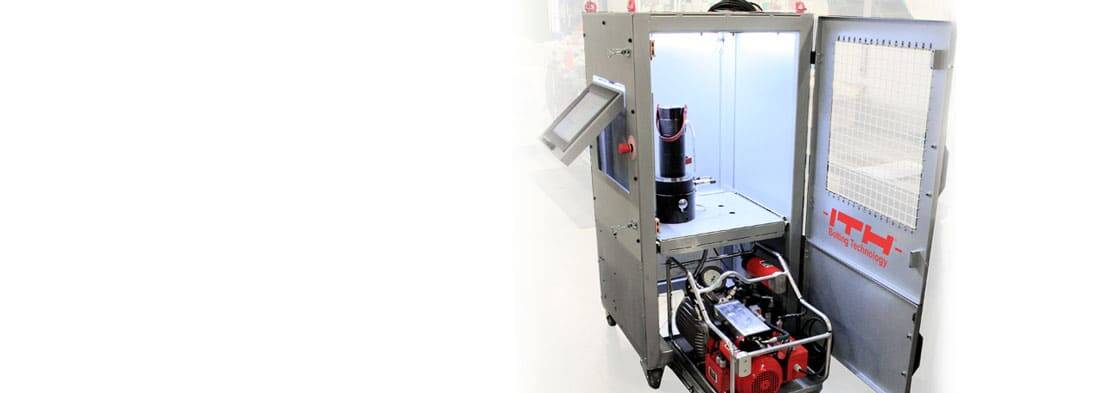

The ITH Bolt Tensioning Cylinder test stand allows automatic testing of bolt tensioning cylinders including the measurement and documentation of the applied pressure in bar.

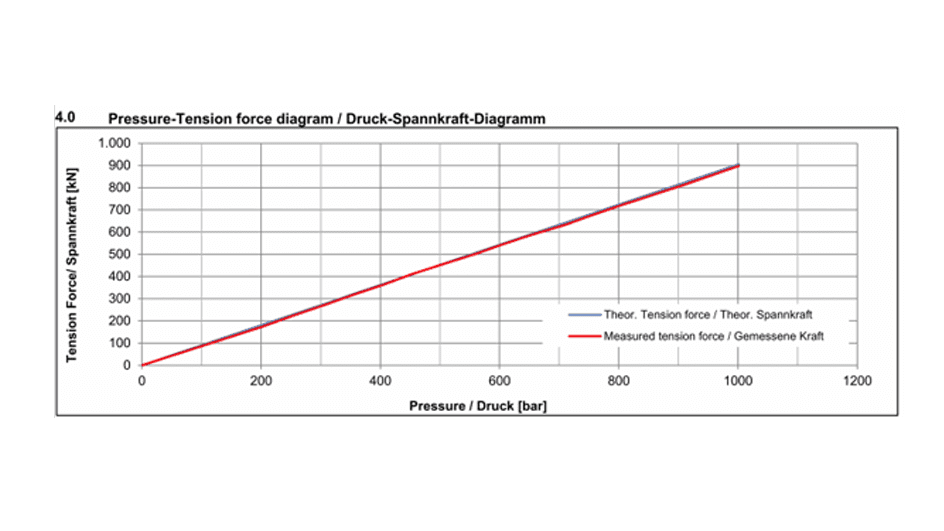

Additionally itcompares the actual versus target performance: the pressure-tension force diagram shows the user clearly a comparison of

- the theoretical force in kN compared to

- the actual applied force in kN.

The testing process is controlled by ITH software.

- The results are automatically saved in an Excel or PDF sheet and are available for additional processing.

- Each test interval is automatic and can be filed systematically.

The testing procedure: Easy and fast usage

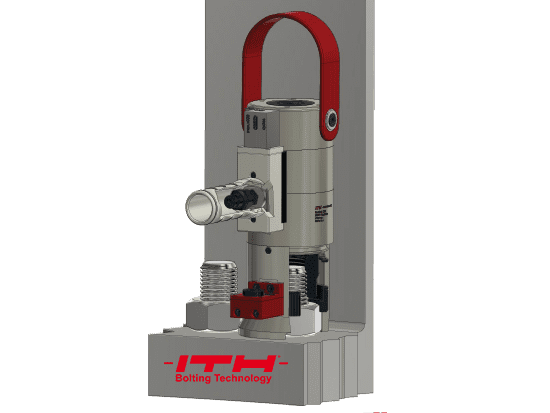

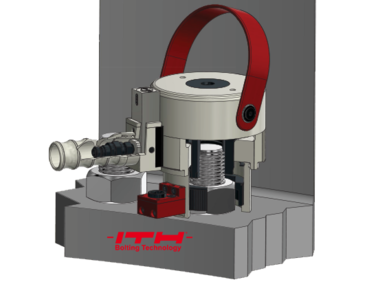

- Test bolts M20 to M72 (3/4" to 3") are directly mounted to the quick-clamp mechanisms of the measuring device.

- The bolt tensioning cylinder is threaded onto the test bolt and the coupling is connected to an integrated ITH hydraulic pump (ITH Hydro-MAX 38 in standard)

- Easy entry of all relevant data with the thouchsreen display:

- Data of the worker

- Data of the customer

- Data of the Tool - After all data is in the system the test procedure starts automatically. The pressure build-up hydraulic pump is controlled automatically by the ITH software.

- The digital documentation system measures and saves the applied pressure and then compares the actual versus target performance: The pressure - force diagram of the theoretical force compared to the applied force in kN.

- The test result documentation can be generated automatically (PDF or Excel-files). The built sheets can be transferred via USB-ports or LAN-connections for any further processing.

- Industrial touchscreen PC

Including the user-friendly ITH management software for automated testing procedures. - ITH hydraulic pump

ITH Hydro-MAX 38 (standard) positioned at the retractable drawer under the testing area. The hydraulic pump is directly controlled by the ITH software of the PC. - Transducer

Test bolts form M20 to M72 ((3/4" to 3") can be mounted at the quick-clamp mechanisms. - Additional features

4 castors (front swivel and lockable), emergency stop switch, 4 eyebolt lifting points for crane transportation, reinforced safety-frame.

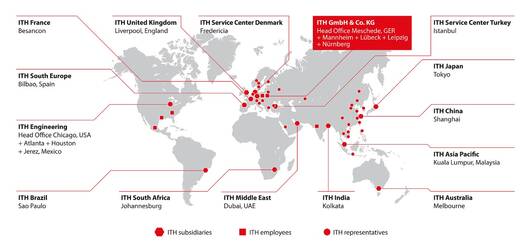

Contact your local person in charge

Use the ITH global network to find your local person in charge.

Objective technical advice

Being a whole system supplier we are not determined to one specific bolting method - Therefore we advise you objectively and offer the best technical and cost-effective solution.

Contact us for a free consultation

Contact us on any questions regarding your bolt connection or for any technical questions. We advise you free of charge and offer a free on-site inspection.

Hydraulic bolt tensioning cylinder test stand: related equipment

-

All types of Bolt Tensioning Cylinders at a glance: fundamental single- and multistage designs, segment cylinders and segment cylinder rings, foundation bolt tensioners and more.

-

Bolt tensioning cylinders with multiple piston surfaces and automatic piston return for high bolting cycles. For applications with axially free and radially limited space.

-

Bolt tensioning cylinders with one piston surface and automatic piston return for high bolting cycles. For applications with axially limited and radially free space.